Solar Atmospheres Eastern PA Commissions 20-Bar High Pressure Gas Quench Furnace

Fabricating & Metal Work

FEBRUARY 20, 2024

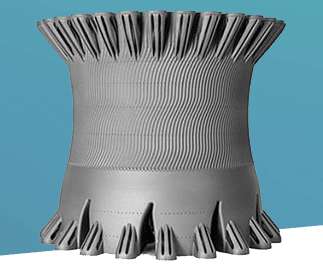

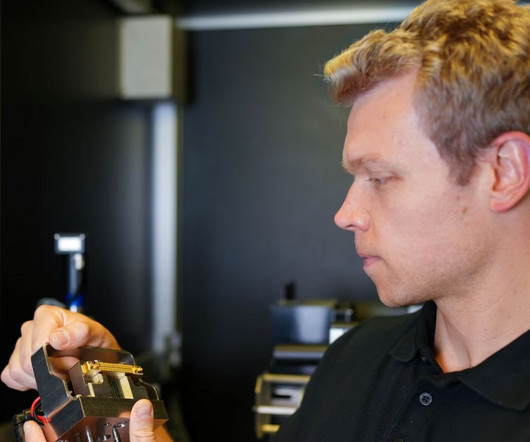

Solar Atmospheres in Souderton, PA recently commissioned a new vacuum furnace capable of utilizing high pressure gas quenching at 20-Bar (about 300 PSI) to meet demanding cooling rate specifications for the heat treatment of nickel-based superalloys. The installation represents an investment of more than $2.5

Let's personalize your content