Technology and Sourcing Guide 2023: Mold Builders

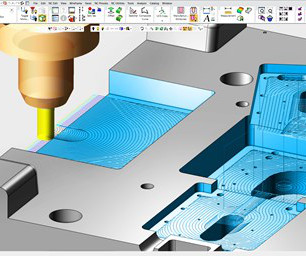

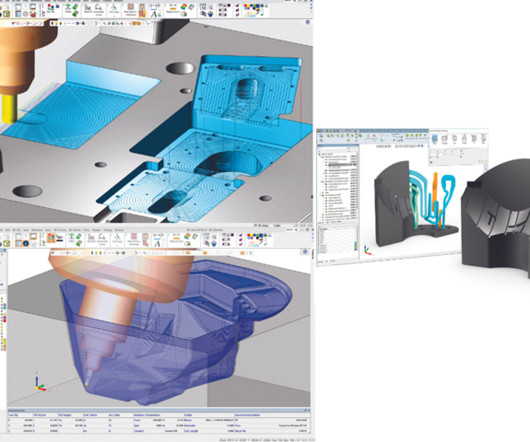

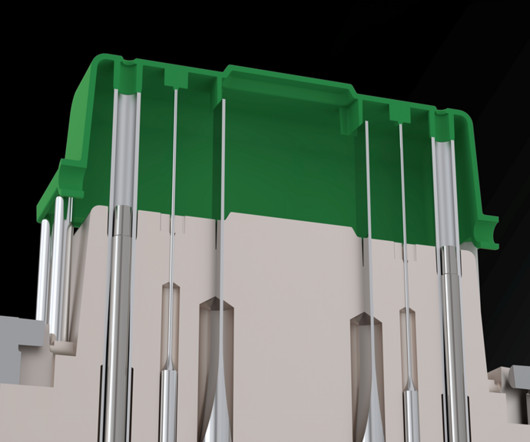

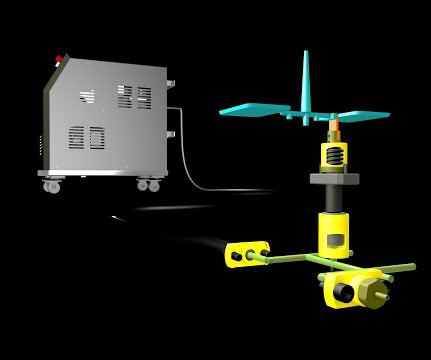

Mold Making Technology

JULY 16, 2023

MoldMaking Technology ’s online database offers more than 1,000 manufacturers, distributors and suppliers for more than 200 product and service categories that you employ daily. This year’s Mold Builders content is exclusively online-only. These are the companies from this section: A1 Tool Corp.

Let's personalize your content