Waterjet Cutting for Multiple Materials

Fabricating & Metal Work

FEBRUARY 16, 2024

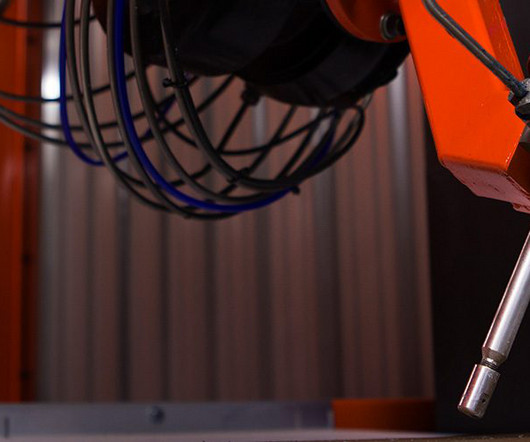

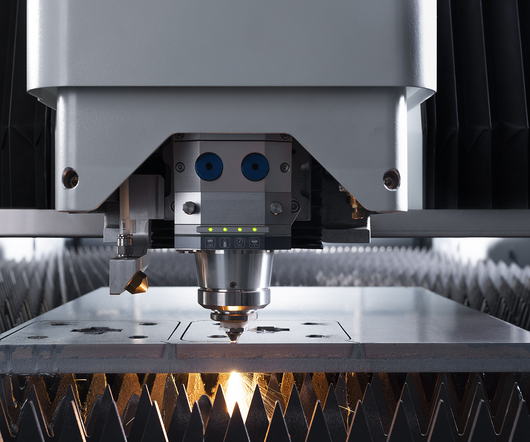

Abrasive waterjet cutting requires a sand supply line and a cutting surface with metal slats. Waterjet cutting uses a highly pressurized stream of water to fabricate parts from more than just metal materials. Despite their differences, both types of waterjet cutting offer three key advantages.

Let's personalize your content