Sojo Industries raises $40M to scale mobile manufacturing lines

Robotics Business Review

JUNE 13, 2025

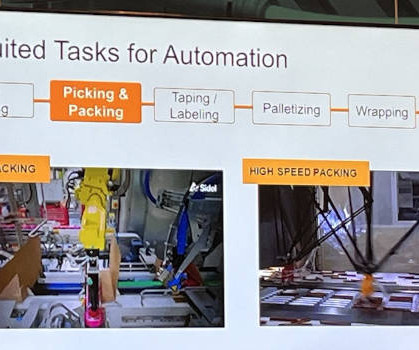

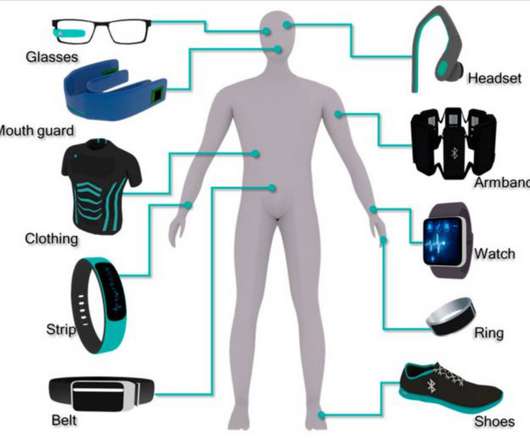

Source: Sojo Industries Sojo Industries, which specializes in advanced robotics, mobile manufacturing, and modular packaging systems, this week said it has raised $40 million. It can also help manufacturers and brands experience dramatic savings on freight and packaging costs. The Bristol, Pa.-based

Let's personalize your content