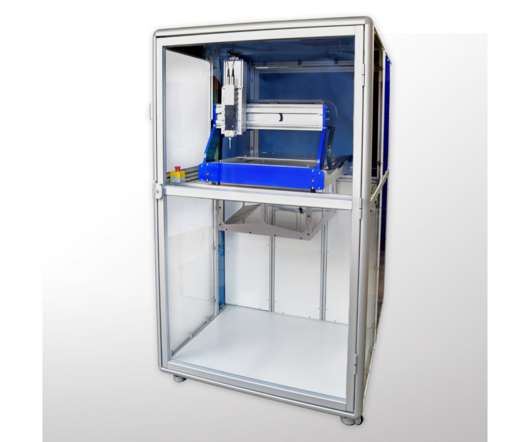

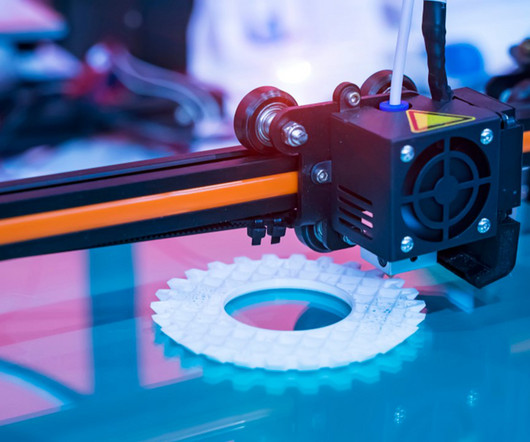

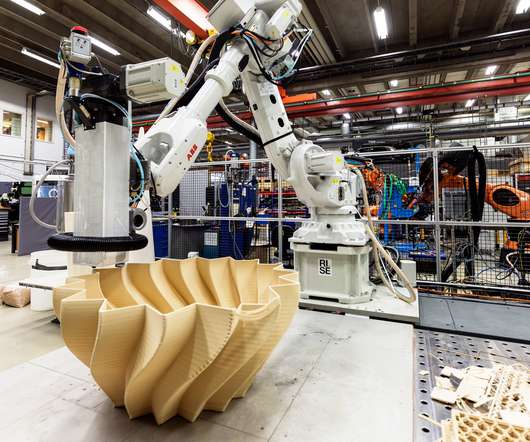

NOVI 3D PRINTER S TEHNOLOGIJOM TRANSPORTNE TRAKE KOJA KORISTI SLA TEHNOLOGIJU

WORCON

MARCH 12, 2024

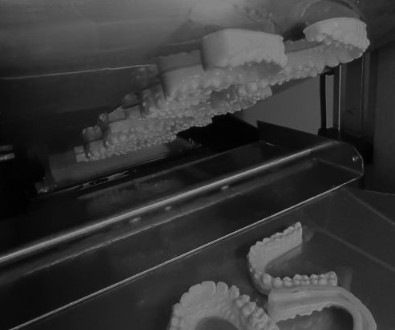

Izraelska start-up tvrtka Sprybuild predstavila je svoj novi Stereolitografski (SLA) 3D pisač s patentiranim kontinuiranim procesom izgradnje na transportnoj traci i čvrstim optičkim sučeljem. Pozivajući se na rezultate istraživanja provedenog između 2017. godine, tvrtka ističe tri glavne prepreke širokom usvajanju 3D printanja.

Let's personalize your content