Why cobots hold the key to unlocking operational efficiency in large manufacturers

Robotics Business Review

APRIL 24, 2024

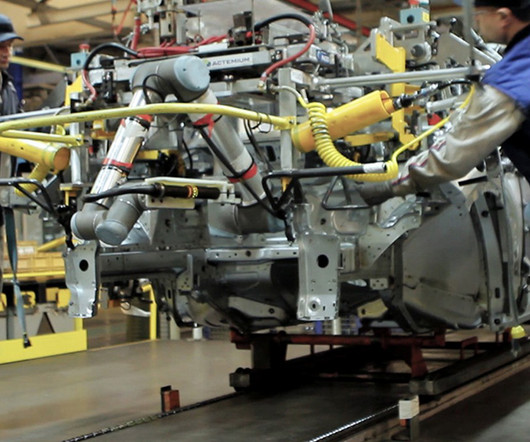

Several of my professional contacts have reached out to ask: Are collaborative robots really just for small and medium-sized companies then? That’s why “new age” robotics, led by collaborative robots and autonomous mobile robots ( AMRs ), has been a game changer for many small to midsize enterprises.

Let's personalize your content