Unscrewing Devices, Hot Runner Systems Advance the Mold

Mold Making Technology

FEBRUARY 22, 2023

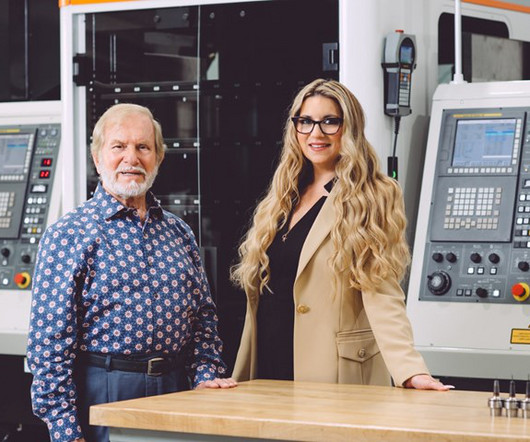

Photo Credit: DME Tooling technology company DME offers its capabilities to assist customers in selecting the correct melt delivery systems, mold configurations and thermal (cooling) systems to ensure parts perform in fit, form and function. Service and component availability is offered in North America, Europe and Asia.

Let's personalize your content