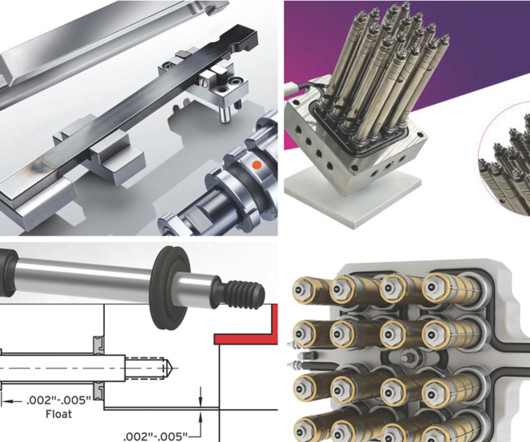

Plate Movement Product Sizing For Mold Tooling

Mold Making Technology

OCTOBER 16, 2024

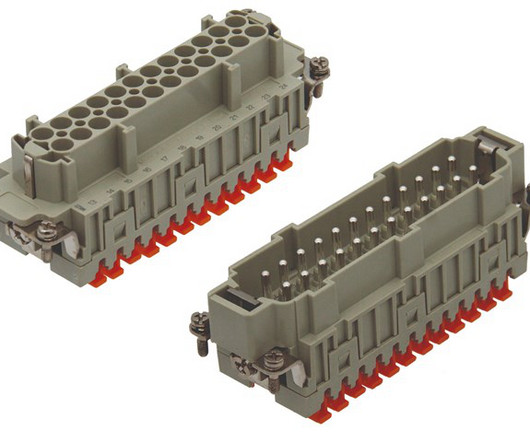

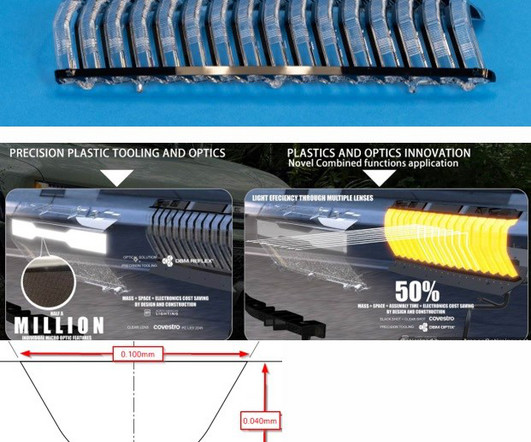

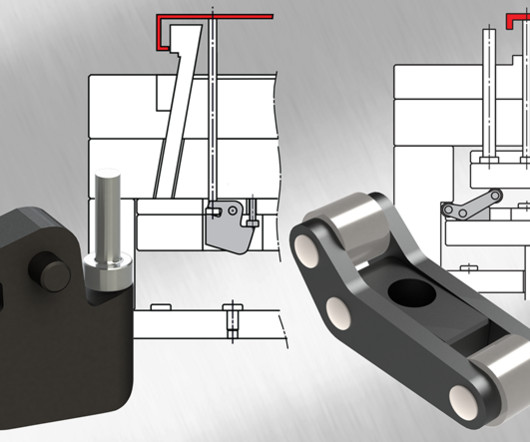

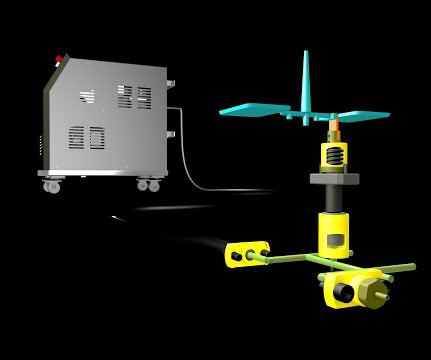

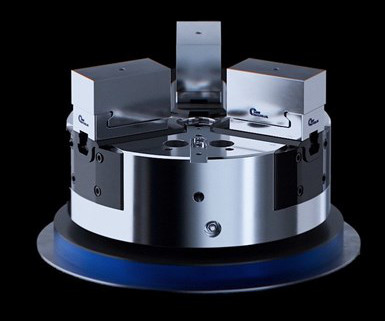

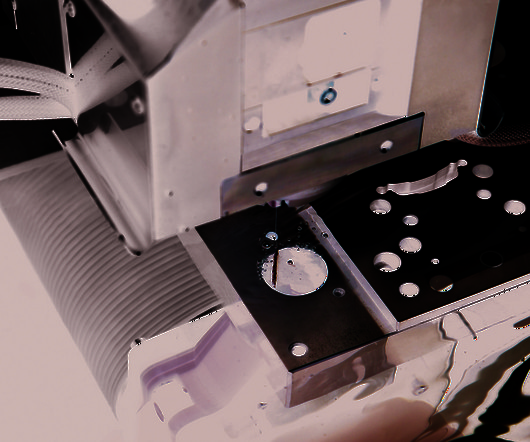

The geometry of planned injection molded component defines the complexity and the amount of work involved in designing and producing the molding tool. At the design phase, one should look closely at the practicality of the molding tool and the complexity of the demolding process. Source | Hasco America Inc.

Let's personalize your content