Conquer Demanding Milling Applications with Reliability and Accuracy

Fabricating & Metal Work

JANUARY 19, 2023

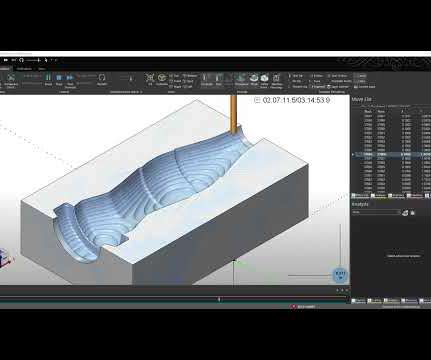

TOOLING & WORKHOLDING H igh cutting speeds , multilayered coatings to increase toughness, and increased material removal rates are some of the benefits of utilizing state-of-the-art e nd mills, thread mills, thread formers and inserts. New Versatile Range of Solid End Mills The Sandvik Coromant CoroMill Dura in action.

Let's personalize your content