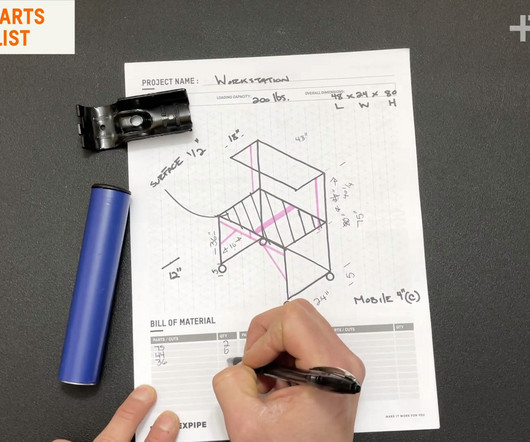

Qld promotes LEAN principles to local manufacturers

AU Manufacturing

SEPTEMBER 2, 2022

The Queensland government is calling on local manufacturers to participate in a series of LEAN manufacturing workshops, which will be held in different parts of the state. . The workshops cost $50 per person and will run until 2 December. . The remaining workshop locations and dates are as follows: .

Let's personalize your content