Lean speakers, Lean tool users and Lean Thinkers

Chris Hohmann

JULY 31, 2022

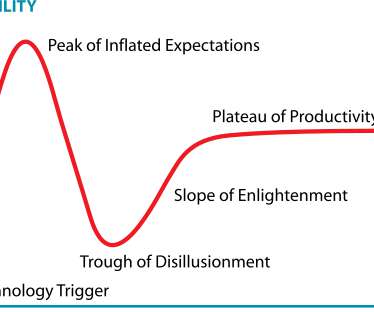

Since awareness about Lean has spread, it seems that Lean experts are plentiful.

This site uses cookies to improve your experience. To help us insure we adhere to various privacy regulations, please select your country/region of residence. If you do not select a country, we will assume you are from the United States. Select your Cookie Settings or view our Privacy Policy and Terms of Use.

Cookies and similar technologies are used on this website for proper function of the website, for tracking performance analytics and for marketing purposes. We and some of our third-party providers may use cookie data for various purposes. Please review the cookie settings below and choose your preference.

Used for the proper function of the website

Used for monitoring website traffic and interactions

Cookies and similar technologies are used on this website for proper function of the website, for tracking performance analytics and for marketing purposes. We and some of our third-party providers may use cookie data for various purposes. Please review the cookie settings below and choose your preference.

lean

lean

Chris Hohmann

JULY 31, 2022

Since awareness about Lean has spread, it seems that Lean experts are plentiful.

Design World

JANUARY 8, 2023

The top goal of most digital transformation (DX) initiatives sounds suspiciously similar to that of lean-manufacturing methodologies — to minimize an operation’s waste and cost while concurrently maximizing its quality (defect-free) throughput of customer-coveted product.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Chris Hohmann

MARCH 27, 2023

The Lean Toolbox Sixth Edition: A Sourcebook for Process Improvement by John Bicheno and Matthias Holweg is out. pounds), gaining a little muscle … Continue reading The Lean Toolbox Sixth Edition: A Sourcebook for Process Improvement

Chris Hohmann

JUNE 5, 2022

This post was inspired by an article published June 1, 2022 by Rick Bohan and Ron Jacques on [link] , titled “Lean Is Futile If Customers Come Last”.

Snic Solutions

MAY 25, 2025

Lean manufacturing is designed to enhance efficiency, minimize waste, and significantly improve product quality. Looking to elevate your manufacturing processes? Master these core principles to streamline your operations and achieve sustained success.

ATS

FEBRUARY 12, 2025

Share Lean manufacturing focuses on eliminating waste and optimizing processes to achieve maximum efficiency and expediency. This means bottlenecks are in many ways the natural adversaries of lean principles. This is why conducting a bottleneck analysis in lean manufacturing operations is such a critical step for manufacturers to take.

Automation World

MAY 30, 2024

Bayer Crop Science shares how it uses Siemens’ Opcenter Intelligence and Insights Hub software to digitally transform its operations around an OEE center point

Gary Mintchell

APRIL 18, 2023

Making Lean Manufacturing more widespread is a good start. Industry Reimagined 2030 just released its research report “ The State of Lean Manufacturing.” Lean Manufacturing continuously eliminates waste, bottlenecks and improves customer value through employee engagement and utilizing data-driven tools. Yet only 10-15% of U.S.

Manufacturing Tomorrow

MARCH 24, 2025

One proven approach to achieving these objectives is the implementation of Lean Manufacturing Principles. Lean manufacturing, a system that emphasizes value creation while minimizing waste, has gained widespread recognition for its ability to streamline operations and reduce costs.

The Fabricator

NOVEMBER 5, 2022

Do you focus on lean tools but ignore the philosophy? Or do you opine about lean philosophy but ignore the tools? Doing either can kill an improvement initiative.

Plastics Today

APRIL 22, 2025

Digital lean, combining lean principles with digital insights, will be explored during a workshop at MD&M East.

The Fabricator

OCTOBER 1, 2022

Are you serious about lean manufacturing, or are you just dabbling? Considering the state of the world, now would be a good time to get serious.

The Fabricator

DECEMBER 29, 2022

After seven years of writing for The FABRICATOR, columnist Jeff Sipes writes his send-off by addressing the past, future, and the fundamentals at lean manufacturing’s core.

MRPEasy

FEBRUARY 28, 2023

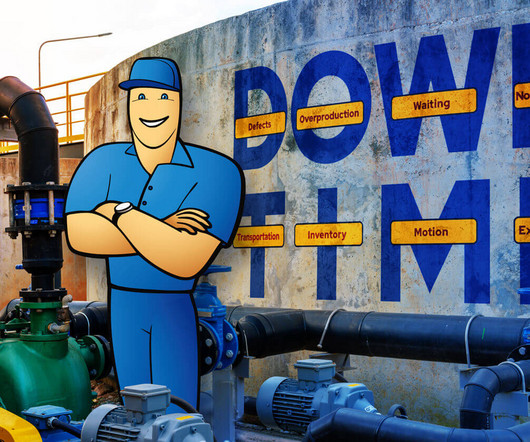

The lean manufacturing methodology chiefly revolves around minimizing production times and raising efficiency by eliminating waste. In this post, we go through the 8 principal wastes in lean manufacturing and see how manufacturing software can help to address them. What is waste in lean manufacturing?

The Fabricator

DECEMBER 1, 2022

Is your metal fabrication shop sustaining your lean manufacturing journey, or are you letting things backslide? It’s time for reflection.

Automation World

JUNE 20, 2023

The new direction announced last year by Siemens Digital Industries Software is already paying off for the company through record growth driven by growing adoption of its SaaS products and its integrated electromechanical and operations technologies.

Granta Automation

DECEMBER 20, 2024

Often the challenges associated with this are multifaceted: managing tight budgets, adhering to stringent timelines, and delivering value to stakeholders … Continue reading → The post Driving Success in Manufacturing Projects: Mastering Project Management and Lean Principles first appeared on Granta Automation.

The Fabricator

AUGUST 29, 2022

Has your metal fabrication shop's lean manufacturing journey stalled or faltered? If so, it’s time for a relaunch.

Automation World

OCTOBER 22, 2024

Strategic data use, safety and integration capabilities are the key factors behind the successful use of computerized maintenance management systems to automate the processes that drive lean, proactive maintenance strategies and increased efficiency.

The Fabricator

AUGUST 1, 2022

Those that resist lean manufacturing efforts need to see the negative impact nonvalue-added activities can have on metal fabrication shops and other facilities.

ATS

JANUARY 8, 2025

Its an essential tool for continuous improvement in Lean and Six Sigma environments and is equally valuable wherever theres a need for root cause analysis. It explores how to create a fishbone diagram and how the fishbone fits within Lean manufacturing. This blog provides a guide to using the fishbone diagram in manufacturing.

Chris Hohmann

JULY 18, 2022

Going to see buy oneself, at the Gemba, is a Lean commandement well received (understood?) by all those who went through a Lean initiation. Now laymen and beginners may ask: where exactly is Gemba? First let’s clarify the meaning of the word Gemba.

Factory Worx

SEPTEMBER 23, 2022

The post What is Lean Manufacturing and its Six Core Principles? appeared first on Factoryworx.

Seeburger

JULY 19, 2022

Lean management methods provide valuable approaches for companies to design their systems more efficiently and sustainably. Value chains are becoming increasingly complex and networked. This is not only due to globalisation, but also to the increasing use of industry 4.0

Chris Hohmann

JUNE 24, 2022

This post is inspired by an article posted June 15th, 2022 on [link] titled “Latest Study from Avery Point Group Concludes: Demand for Lean Professionals Remains Strong, While Six Sigma Talent Demand Continues to Decline”.

Manufacturer's Monthly

APRIL 29, 2024

The post Lean, green lifting machines appeared first on Manufacturers' Monthly. “And we just keep on developing.” Combilift will fully supply lithium-ion trucks to customers upon request, recognising the industry’s anticipated growth to accommodate lithium recycling.

Manufacturer's Monthly

MARCH 19, 2025

The Lean Manufacturing Pilot Program will provide small-to-medium-sized manufacturers across regional NSW with funding to undertake audits by professional consultants that will identify ways to re-organise their manufacturing operations.

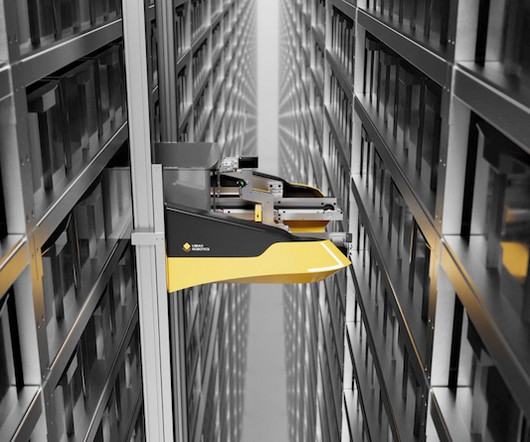

Robotics Automation News

MAY 15, 2025

A compact and agile AirRob automated storage system by Libiao Robotics has been installed in the Shanghai warehouse of a specialist lean supply chain management service company.

Manufacturer's Monthly

MARCH 25, 2025

The Lean Manufacturing Pilot Program will provide small-to-medium-sized manufacturers across regional NSW with funding to undertake audits by professional consultants. The Lean Manufacturing Pilot Program will help support local manufacturers to improve their operations and continue to go from strength to strength.

Industry Week

NOVEMBER 27, 2023

Digital works best when it’s pulled in to add value for specific process improvements.

MRPEasy

JANUARY 13, 2025

Lean manufacturing tools help you organize workspaces and fix problems before they can slow you down. What is lean manufacturing? Lean manufacturing is all about working smarter, not harder. At its core, its […] The post Top 15 Lean Manufacturing Tools in 2025 appeared first on Blog for Manufacturers and Distributors.

The Fabricator

JUNE 7, 2024

Experts reveal that starting a continuous improvement campaign in the welding department isn't as hard as a metal fabrication shop might think. Jason Becker from Underground Metal Works and Brian Engelhardt from MERRILL Technologies (No. 13 on the 2024 FAB 40), weigh in.

eFlex Systems

NOVEMBER 12, 2024

See how lean principles and modern tools tackle defects, overproduction, and more. Explore practical solutions for real-world manufacturing challenges.

The Fabricator

OCTOBER 6, 2023

The same continuous improvement tools that help metal fabricating operations to hum can help with the assembly department as well.

Fabricating & Metal Work

MARCH 31, 2025

LEAN Manufacturing Products is thrilled to announce the launch of our Universal Cartridge Design and Modular Rack System, engineered to optimize your lean manufacturing operations. Transform your lean manufacturing processes today with our innovative Configurator.

eFlex Systems

DECEMBER 6, 2024

Explore practical ways modern manufacturing tech reduces transportation and inventory waste, driving efficiency and profitability in lean operations.

eFlex Systems

NOVEMBER 27, 2024

Discover how modern manufacturing tech tackles Lean wastes like Waiting & Underused Talent in this blog, boosting efficiency, training, and ROI.

The Fabricator

JANUARY 23, 2025

Jake LeGrand discusses his passion for plasma cutting, his one-man shop in Missouri, and turning an empty water tank into a campground fire pit.

The Fabricator

MARCH 17, 2025

The only way that lean manufacturing techniques can work for job shops is if they adapt the concept to meet their own manufacturing realities.

Manufacturing Tomorrow

JANUARY 6, 2025

Technoset Ltd, which employs 27 people at its factory in Rugby, took learnings from a Warwickshire Manufacturing Growth Programme lean workshop to create a more streamlined process flow and a world class production and inspection cell.

Robotics Business Review

DECEMBER 23, 2024

This is exacerbated by the fact that manufacturers carry less and less inventory in an effort to keep costs lean. To beat the competition, engineers must shrink development times, optimize product performance and traverse an ever-growing number of supply chain issues.

Robotics Automation News

JANUARY 16, 2023

To some extent, the automotive sector has already adopted lean principles. The DevOps pipeline holds remarkable similarities to how the automobile sector works. Workers neatly assemble different parts to construct an entire vehicle. The automotive industry has […].

The Fabricator

JANUARY 24, 2023

Longtime industry consultant Gary Conner recalls his days implementing lean manufacturing concepts and eliminating waste in the sheet metal job shop.

Chris Hohmann

JULY 26, 2023

Value Stream Mapping (VSM) is popular and hype to a point it makes it a kind of Lean emblem. An academic mocked a company’s low Lean maturity for not displaying any Value Stream Map. It was not only shocking to my ears, but proved the academic’s own low maturity on the subject.

Expert insights. Personalized for you.

We have resent the email to

Are you sure you want to cancel your subscriptions?

Let's personalize your content