Machine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

Modern Machine Shop

JULY 23, 2024

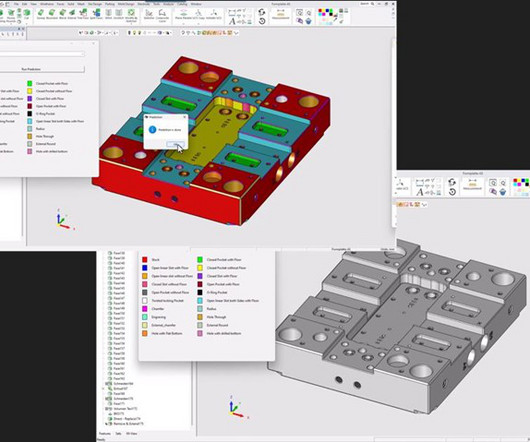

At the heart of the milling spindle of a CNC machine tool is a vital yet simple component with an outsized effect on the lead time and environmental impact of the spindle’s production. Source: DMG MORI This Lasertec model provides for turning; milling and drilling; and powder-fed DED in one cycle.

Let's personalize your content