SCADA’s role in Industry 4.0, manufacturing applications

Control Engineering

JULY 31, 2023

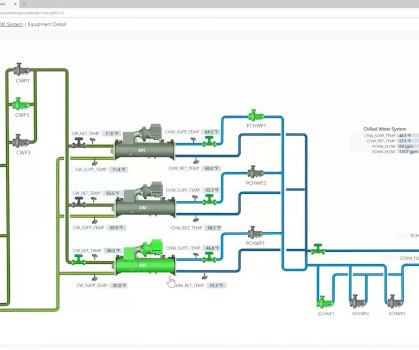

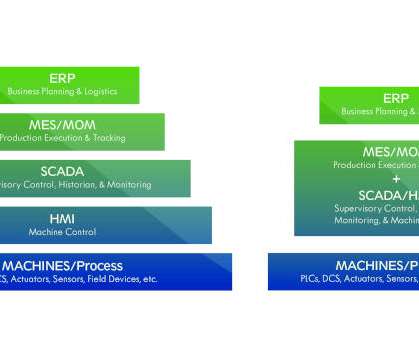

SCADA insights SCADA systems have evolved significantly with the rise of IT/OT convergence and Industry 4.0. They are no longer just monitoring tools but are shaping the future of smart factories, thanks to open system architecture and the ability to integrate data from IT and OT sources. To achieve Industry 4.0

Let's personalize your content