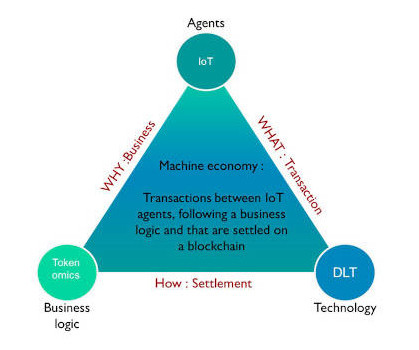

Industry 4.0 and Lean Management – How to Manage the Chaos

Seeburger

JULY 19, 2022

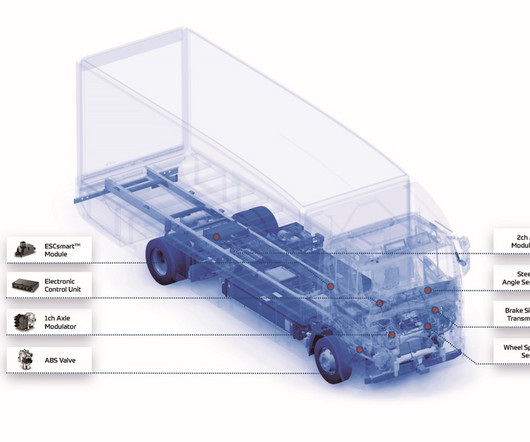

Value chains are becoming increasingly complex and networked. This is not only due to globalisation, but also to the increasing use of industry 4.0 This article looks at the demands these approaches place on data logistics and how […].

Let's personalize your content