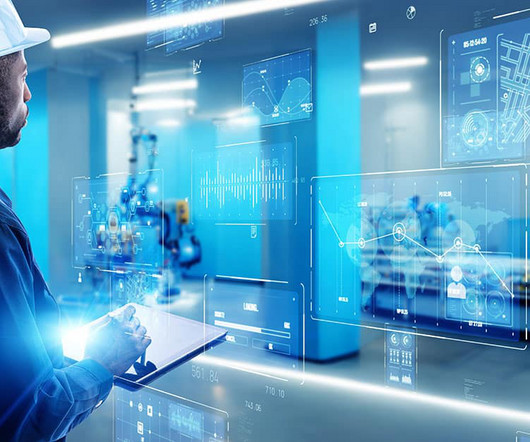

Is Industry 4.0, smart manufacturing working for you?

Control Engineering

JULY 12, 2023

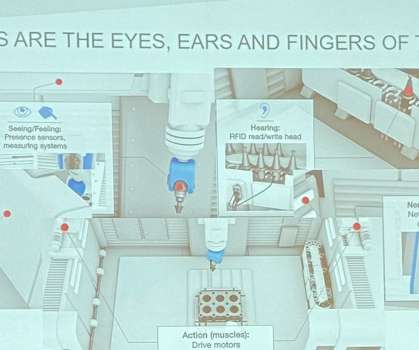

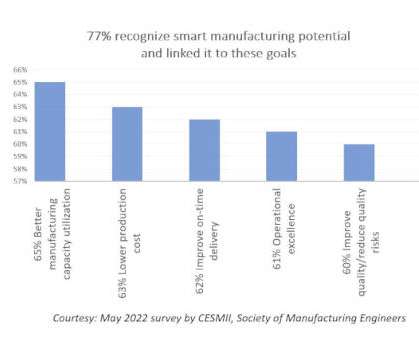

Learning Objectives Identify how to determine if your company is moving quickly enough with Industry 4.0 Review differences in Industry 4.0, smart manufacturing and digital transformation. Understand Industry 4.0 It has been a dozen years of Industry 4.0 Is there an Industry 5.0?

Let's personalize your content