Reducing scrap and risk at plastic facility

Control Engineering

DECEMBER 1, 2022

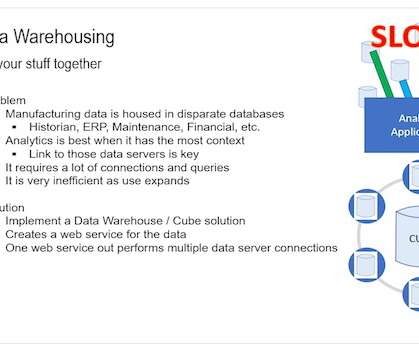

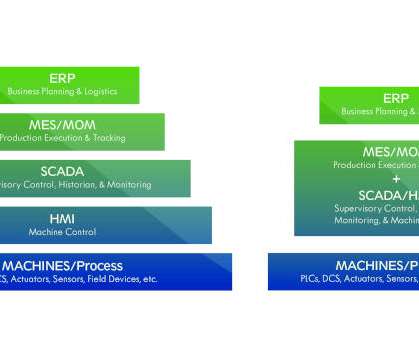

A plastic manufacturer wanted to overhaul their legacy control system to reduce inefficiencies and waste. The system integrator chosen for the project improved process control and information flow to provide real-time data through the enterprise resource planning (ERP) system. MORE ANSWERS.

Let's personalize your content