Driving Excellence in Precision Manufacturing with GROB Machine Tools

Dinesh Mishra

JANUARY 22, 2025

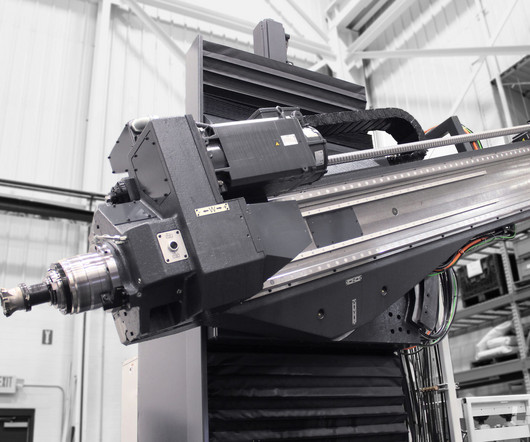

1 ) What recent advancements in metal-cutting technology have had the most transformative impact on efficiency and precision? GROB machine tools have become a driving force in modern metal-cutting technology, offering a blend of advanced features that not only enhance efficiency but also redefine the standards for precision manufacturing.

Let's personalize your content