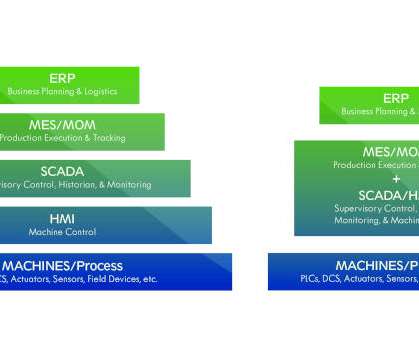

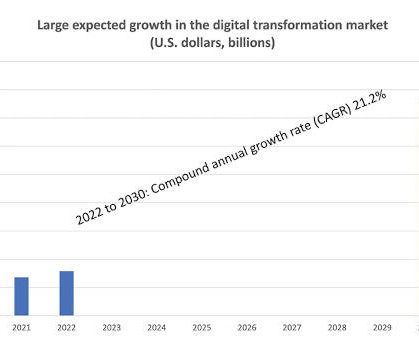

Plant Documentation 4.0 – An Essential Enabler for Industry 4.0

i4.0 today

MARCH 2, 2023

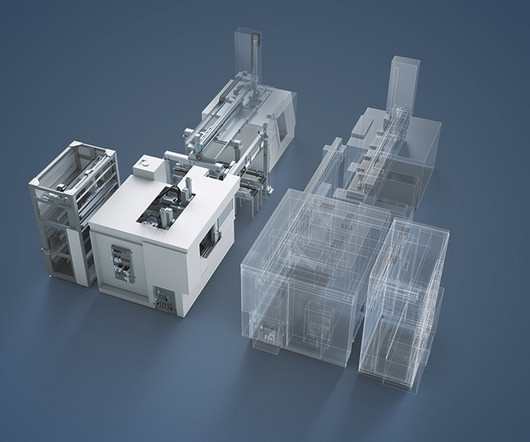

Reliable documentation of as-built status As-built documentation – meaning documentation that reflects the actual state of a new plant – has always been required for commissioning, but in fact the time and resources involved in preparing the relevant documents is always immense.

Let's personalize your content