Critical Manufacturing and L&T Technology Services to Support Danfoss’ Smart Manufacturing Journey

i4.0 today

MAY 25, 2023

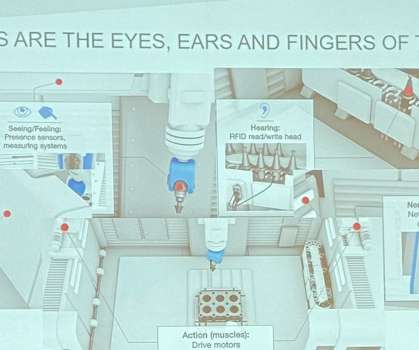

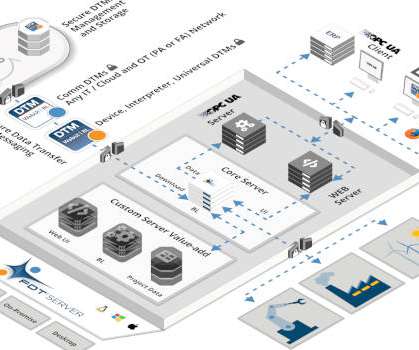

The Critical Manufacturing MES is designed from the ground-up to embrace Industry 4.0 technologies and provide a comprehensive pathway to smart manufacturing of sophisticated and complex products. success, will enable us to drive better business outcomes for our manufacturing and industrial clients.”

Let's personalize your content