Myth, Revolution or Solution?

MEM

SEPTEMBER 22, 2023

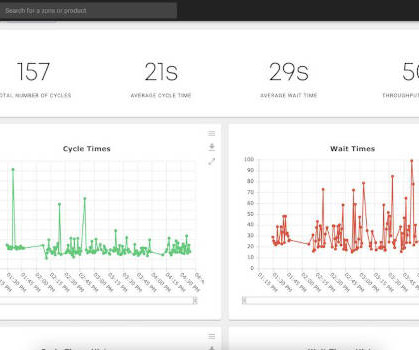

In recent tests using the latest generation of Viper wheels, Tyrolit were able to decrease cycle time by as much as 30%. Considering consumable unit costs at approximately £25 each (Viper wheel) and machine platform at £150* per hour, a 30% time saving reduction = £45; outweighing the cost of the consumable in one hour!

Let's personalize your content