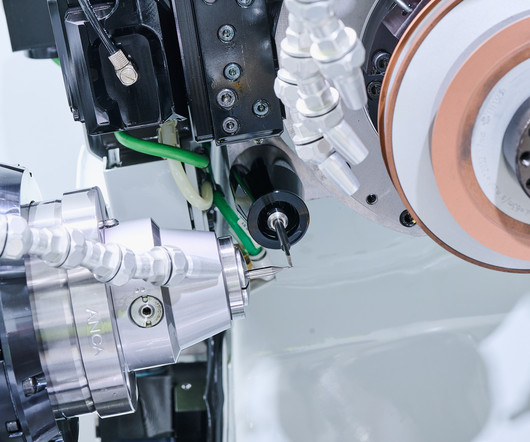

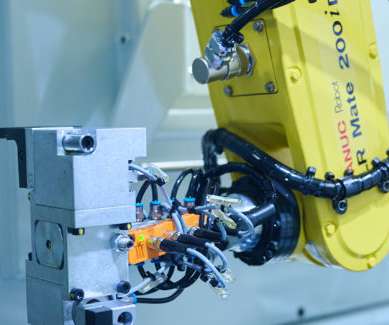

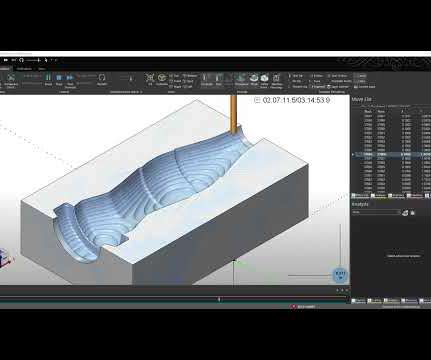

ANCA Offers Grinding Machine for Manufacturing Cutting Tools

Modern Machine Shop

JANUARY 15, 2023

New software, hardware and design features advance surface finish, accuracy and controlled runout capabilities. ANCA’s newly designed servo control algorithm enables smooth motion of an axis with the use of a unique algorithm and nanometer measurement in the control system.

Let's personalize your content