How Industry 4.0 Influence Today’s Asset Management

Factory Worx

AUGUST 3, 2022

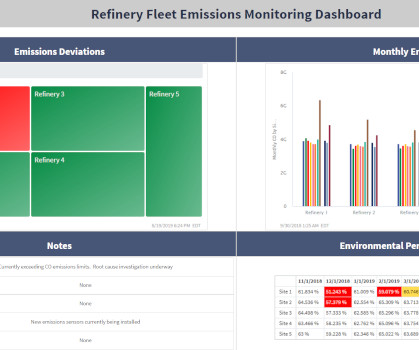

How Industry 4.0 The next generation of asset management systems, designed to be intelligent, automated, and cost-effective, is now being driven by the digital transformation of industrial processes. However, transitioning from present paradigms to Industry 4.0 Industry 4.0 Industry 4.0

Let's personalize your content