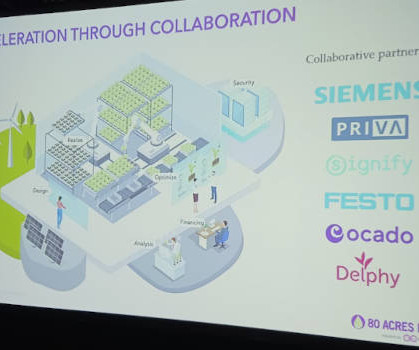

Collaborate, improve resilience in an industrial automation supply chain

Control Engineering

JULY 14, 2023

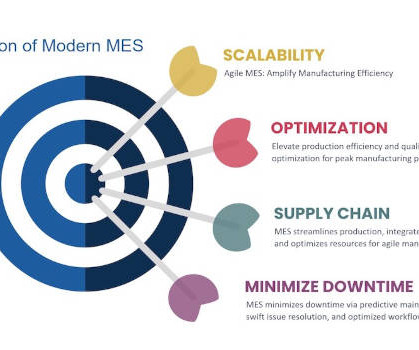

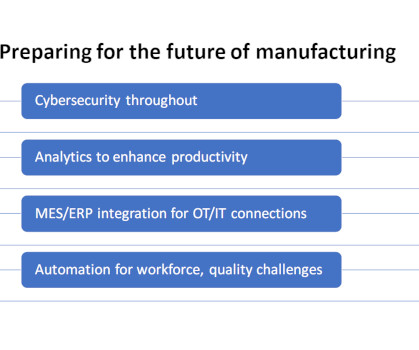

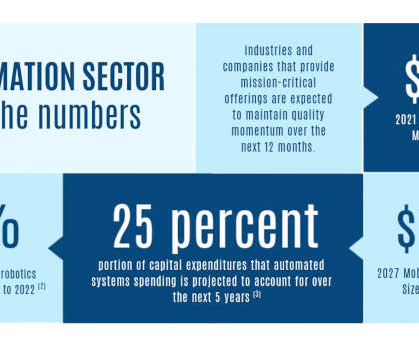

Learning Objectives Understand how rapid changes in supply chains created a need to share more information more effectively. Learn the advantages of improving data transparency for supply chains. See how tools can increase supply chain digitalization, integration and automation.

Let's personalize your content