MES and ERP Data Integration

ATS

MAY 1, 2025

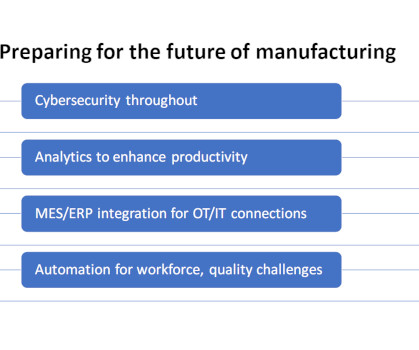

Share Manufacturing execution systems (MES) and enterprise resource planning (ERP) tools both play critical roles in production line performance. Manufacturing execution systems (MES) provide real-time monitoring and control of production operations.

Let's personalize your content