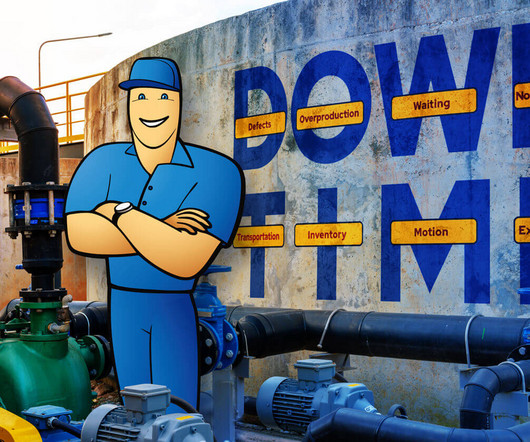

The 8 Wastes of Lean Manufacturing

MRPEasy

FEBRUARY 28, 2023

The lean manufacturing methodology chiefly revolves around minimizing production times and raising efficiency by eliminating waste. In this post, we go through the 8 principal wastes in lean manufacturing and see how manufacturing software can help to address them. What is waste in lean manufacturing?

Let's personalize your content