Digitizing an entire factory to Industry 4.0

Quantis

NOVEMBER 22, 2022

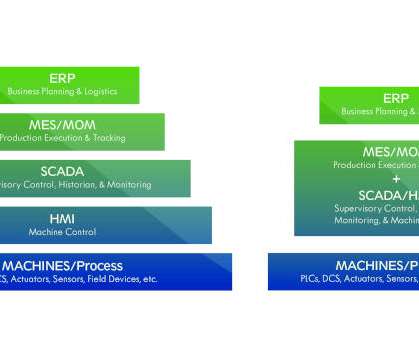

The added value of converting individual lines to Industry 4.0 At the end of the project, the customer received detailed documentation on all available data, which was made available for processing by other IT systems. The conversion of the entire factory to Industry 4.0

Let's personalize your content