Five-Axis Turnkey Machine Halves Medical Shop’s Cycle Times

Modern Machine Shop

FEBRUARY 18, 2024

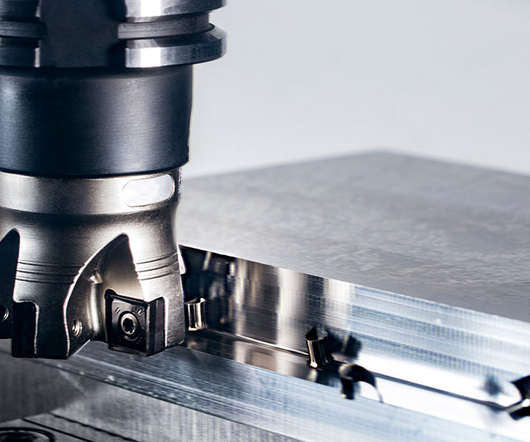

It combined work previously requiring two turning operations and one milling operation, completing the job in half the time of the original process. The machine’s expanded capacity from its pallet system has also enabled the facility to use the G550 for other large parts, where it often cuts cycle times by as much as 50%.

Let's personalize your content