Manufacturing robot installed base to reach 16.3M by 2030, says ABI Research

Robotics Business Review

JANUARY 20, 2025

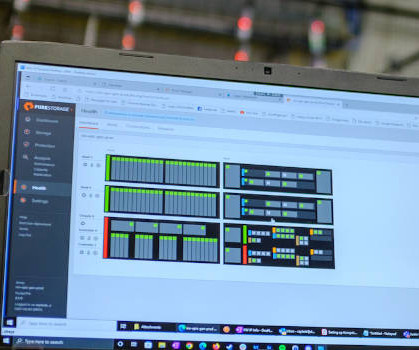

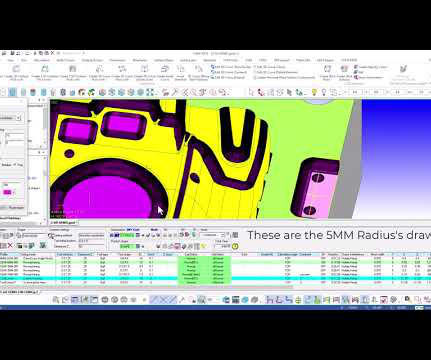

Source: Adobe Stock In January 2024 , the U.S. Manufacturers to capture data, turn to automation Staffers at manufacturers need to be more data-savvy, said ABI Research. For example, technicians are concerned with avoiding unplanned downtime and improving a machine’s overall equipment effectiveness (OEE).

Let's personalize your content