Protecting the digital manufacturing supply chain while promoting innovation

Control Engineering

SEPTEMBER 14, 2022

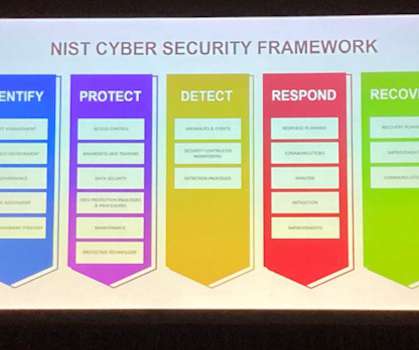

Manufacturing Supply Chain Insights. Manufacturing is the No. Many small and midsized manufacturers assume their limited profile shields them from being targeted in cyberattacks, the opposite is often true thanks to the supply chain. defense industrial base and supply chain.

Let's personalize your content