Collaborative Engineering Drives Quality Mold Solutions

Mold Making Technology

NOVEMBER 24, 2024

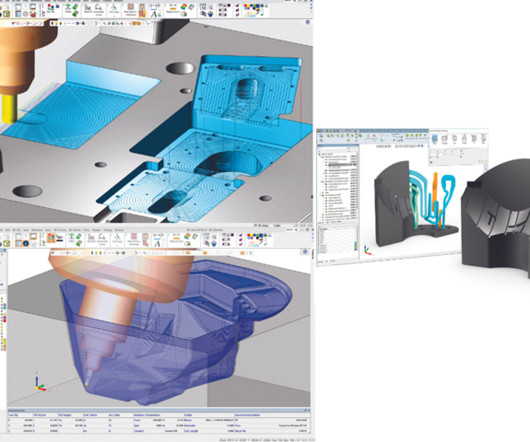

This team is involved in the design, development and maintenance of high-precision molds, including multi-cavity and complex molds used in various industries such as automotive, medical and consumer goods. CNC milling and sinker EDM machines use multi-pallet automation with robotic tending to run parts fully unattended.

Let's personalize your content