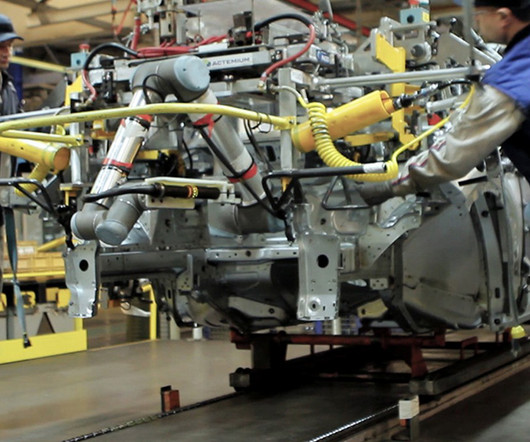

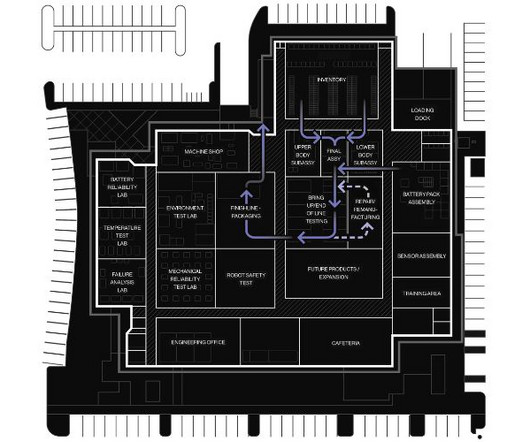

Massimo Motor adds mobile robots to production line for UTVs

Robotics Business Review

DECEMBER 26, 2024

Source: Massimo Group Massimo Motor Sports LLC, a manufacturer and distributor of powersports vehicles and pontoon boats, has added robotics to its new assembly line to streamline production and enhance quality control. These UTVs are part of the company’s best-selling T-Boss line.

Let's personalize your content