Packaging Robots Market to Worth US$ 7.5 Billion by 2032 at a CAGR of 7%

i4.0 today

MARCH 30, 2023

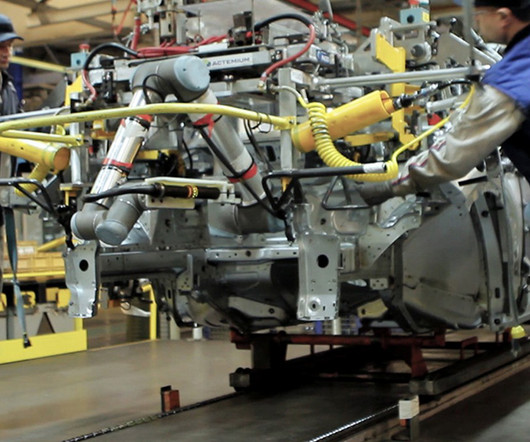

To produce standard packaging and customized packaging, manufacturers in the food and beverage sector are shifting from traditional assembly line techniques toward completely automated assembly lines. These insights are based on a report on Packaging Robots Market by Fact.MR. Today Magazine.

Let's personalize your content