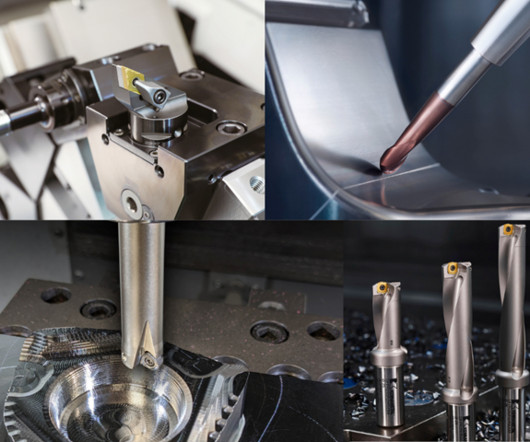

Machining is More Than Geometry

Modern Machine Shop

APRIL 25, 2024

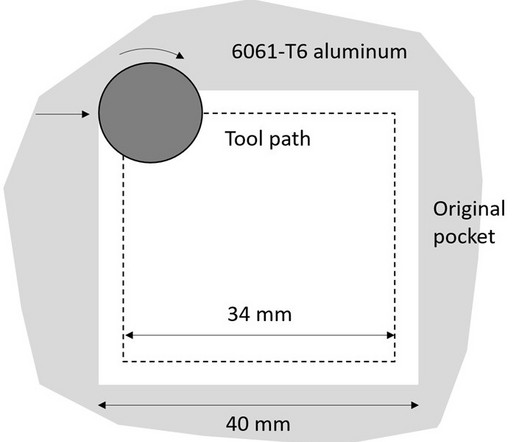

The introduction of CNC for machining centers enabled a digital approach, where the desired part is defined by a solid model produced using CAD software. The CNC tool paths used to machine this part are then generated using CAM software. Tool wear occurs because machining is a competition between the sharp cutting edge and workpiece.

Let's personalize your content