Helping assembly-line robots pick up objects

Control Engineering

AUGUST 3, 2022

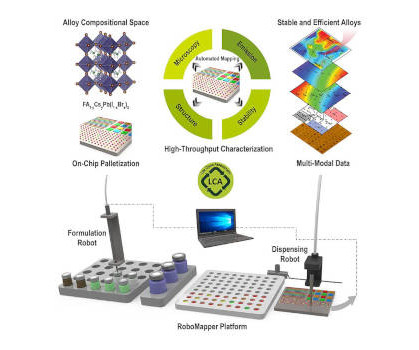

Robotics Insights. Improving robots’ ability to grip and handle objects has been a major challenge for manufacturers because it limits what they can do on the plant floor. To make this switch possible, these companies relied on people working on an assembly line. Courtesy: University of Washington. “We

Let's personalize your content