Robot Setup Gets Automated

Automation World

JANUARY 31, 2023

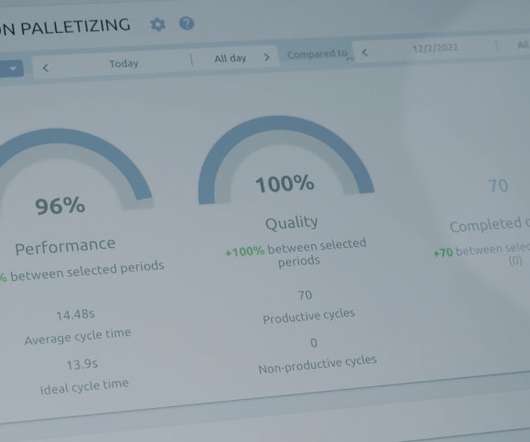

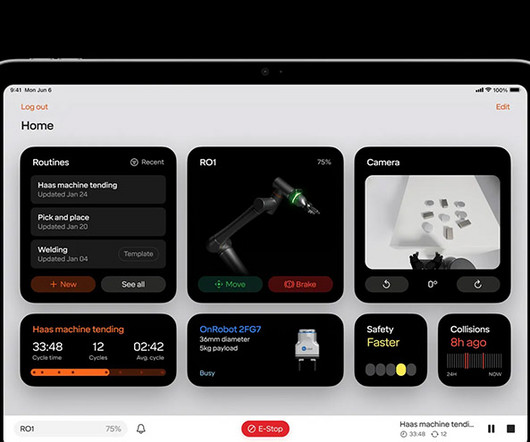

OnRobot’s D:Ploy hardware and software is now available to automate the process of integrating robots into palletizing, CNC machine tending, packaging, and pick-and-place applications.

This site uses cookies to improve your experience. To help us insure we adhere to various privacy regulations, please select your country/region of residence. If you do not select a country, we will assume you are from the United States. Select your Cookie Settings or view our Privacy Policy and Terms of Use.

Cookies and similar technologies are used on this website for proper function of the website, for tracking performance analytics and for marketing purposes. We and some of our third-party providers may use cookie data for various purposes. Please review the cookie settings below and choose your preference.

Used for the proper function of the website

Used for monitoring website traffic and interactions

Cookies and similar technologies are used on this website for proper function of the website, for tracking performance analytics and for marketing purposes. We and some of our third-party providers may use cookie data for various purposes. Please review the cookie settings below and choose your preference.

applications machine-tending

applications machine-tending

Automation World

JANUARY 31, 2023

OnRobot’s D:Ploy hardware and software is now available to automate the process of integrating robots into palletizing, CNC machine tending, packaging, and pick-and-place applications.

Automation World

SEPTEMBER 20, 2022

As seen in two applications from Robotiq and Versabuilt using Universal Robots’ cobots, machine tending applications are becoming a key aspect of collaborative robot use in industry—especially in high mix, low-volume manufacturing.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Gary Mintchell

NOVEMBER 15, 2024

I tend to like the research coming from Interact Analysis. She continues, “This has been affecting sales of industrial automation components to machine builders (OEMs), including motion control products. Their methodology appears to be more rigorous than others that come my way.

Robotics Business Review

NOVEMBER 20, 2024

By integrating the ‘legs’ of a mobile robot with the ‘arms’ of a cobot, the MC600 addresses multiple automation workflow challenges such as palletizing and machine tending with one system,” said Jean-Pierre Hathout, president of Mobile Industrial Robots ( MiR ). The proposed standard describes an example apparatus for testing.

Gary Mintchell

MARCH 18, 2025

This news expands AI-powered applications. The unveiling represents the first public demonstration of the AI Accelerator in commercially viable applications. T-Robotics – GenAI Driven Programming: Demonstrating a UR5e cobot with LLM-driven CNC machine tending. Many are based on Universal Robotics technology.

i4.0 today

APRIL 4, 2025

Bringing together SICKs sensor expertise with the worlds largest cobot vendor for seamless teamwork, distributors predict it will generate new sales opportunities and applications. It’s a good product and a good solution and I can’t wait to start looking at applications for it.

Gary Mintchell

DECEMBER 18, 2024

Event Highlights: Hands-On Demonstrations: Attendees can explore 30+ different cobot-powered solutions for applications such as welding, quality inspection, material handling, machine tending, assembly, painting, and palletizing. The hands-on demos are presented by UR and its UR+ ecosystem partners including A.I

Robotics Business Review

MARCH 26, 2025

The company said the new release delivers more powerful capabilities for machine tending, quality control, and robotic production. FlexCORE does this by enabling both industrial and collaborative robots to run multiple machines with multiple operations for multiple part SKUs, said Flexxbotics. Register now so you don't miss out!

Gary Mintchell

AUGUST 30, 2024

UR leaps on the AI bandwagon at IMTS announcing an AI-powered machine tending solution. By adding high-performance compute hardware to our control systems and investing in targeted software upgrades, we’re establishing UR as the preferred robotics platform for developing and deploying AI applications.”

Design World

DECEMBER 13, 2022

Combining speed and accuracy with expanded load handling capability of up to 11 kg, the SWIFTI CRB 1300 can be used in a wide variety of production and product-handling applications – from machine tending and palletizing to… The post New SWIFTI industrial cobot delivers speed, accuracy, and safety appeared first on Design World.

Automation Mag

MARCH 17, 2025

Developed for manufacturers across the Midwest and Southern Ontario challenged by labor shortages and increased production goals, KUKAs interactive curriculum featured autonomous mobile robots (AMRs), automated machine tool solutions and welding robotics. The KR FORTEC is suitable for a wide range of applications.

Automation Mag

APRIL 8, 2025

Currently available standardized solutions meet a variety of application needs, including palletizing, machine tending, welding and inspection, among others. The CRX line of cobots are available in payloads up to 30 kg with a reach of up to 1889 mm, with models specific to painting as well as food-grade cobots available.

Design World

SEPTEMBER 25, 2023

Rachel Luczak, Application Engineer, B&R Industrial Automation Bachelor of Science in Electrical Engineering Milwaukee School of Engineering I am an Application Engineer working in the Milwaukee Office for B&R Industrial Automation.

Gary Mintchell

SEPTEMBER 11, 2024

Named after the popular open-source Arduino platform and development partner ASTOR, Astorino leverages Kawasaki Robotics’ extensive technology expertise, including hardware, firmware, control system, application software and training. The platform also supplies STL files so students can rapidly print 3D replacement parts for 99% of the robot.

Robotics Business Review

JUNE 10, 2024

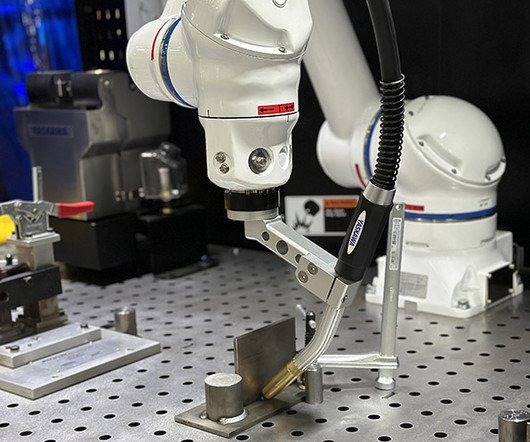

Mitsubishi’s ARIA standard (left) and machine tool tending base (right). “ARIA is fully configurable and mobile, making it an ideal solution to tackle multiple applications within a given facility.” The company offers two base options for the system — standard and machine tool bases.

Robotics Automation News

DECEMBER 18, 2022

Combining “class-leading” speed and accuracy with expanded load handling capability of up to 11 kg, the Swifti CRB 1300 can be used in a wide variety of production and product handling applications – from machine tending and […].

Gary Mintchell

JANUARY 23, 2023

Just as I thought robotics was a pretty stagnant market, cobots arrived to bring automation to applications previously too small for the size and expense of industrial robots. With protection against dust and moisture (up to IP67), it can also be used in demanding environments, making it ideal for machine tending applications.

Gary Mintchell

JANUARY 31, 2023

We are going to continue seeing phenomenal growth within complete robotic systems for applications such as welding, palletizing and machine tending, propelled by UR partners creating full solutions powered by our collaborative robot arms.” A significant share of new cobot-powered turnkey systems now handle welding applications.

Robotics Business Review

FEBRUARY 27, 2024

Ruland Manufacturing has chosen Flexxbotics FlexxCORE technology for its robotic machine tending needs. The machine-tending system from Flexxbotics enables Ruland’s collaborative robots from Universal Robots to communicate directly with its FANUC RoboDrill machinery and Renishaw inspection probes.

Automation World

JUNE 21, 2024

Two new electrical grippers for heavy-duty, collaborative robot applications were announced at Automate 2024 in addition to the new AutoPilot machine tending software for D:Ploy developed with Ellison Technologies.

Robotics Business Review

MAY 10, 2024

“As cobots grow more powerful, OnRobot customers are scaling up their collaborative applications,” stated Enrico Krog Iversen, CEO of OnRobot. and industrial robot arms are being deployed in collaborative applications, observed OnRobot. and industrial robot arms are being deployed in collaborative applications, observed OnRobot.

Control.com

MAY 8, 2024

OnRobot has launched two new electric grippers capable of handling high-payload applications and partnered with Ellison Technologies to power a CNC machine-tending solution.

Gary Mintchell

DECEMBER 13, 2024

Building on the success of the smaller MC250, the MC600 offers a powerful comprehensive system for handling heavier items and automating tasks such as palletizing, box handling and machine tending.

The Fabricator

APRIL 14, 2023

Destaco has announced the availability of cobot tooling for applications employing small payload robots or cobots.

Modern Machine Shop

FEBRUARY 7, 2023

Tending, warehouse and secondary operations all see improvement from implementation of these robots, reducing costs and improving profits per square foot. Tending Operations Deploying robots for machine tending often improves throughput and operational safety while maximizing overall equipment effectiveness.

Gary Mintchell

NOVEMBER 29, 2023

Central western Ohio had several companies that manufactured special tube-bending machines. This smaller size allows it to adapt to more application areas. A structural benefit comes from the smaller size leading to a more rigid structure allowing it to hold its arm steady in high-torque screw driving applications.

Robotics Business Review

MAY 1, 2024

based, employee-owned firm has a global customer base for its broad CNC machine and tooling lines. The phrase describes fully automating production runs of machined goods, so no one is needed to oversee the CNCs producing them. What sets Tormach’s machines and tooling portfolio apart from what other companies offer?

Mold Making Technology

FEBRUARY 27, 2025

A typical prototype mold takes three to seven days for the company to machine out of steel. Deep ribs and small details require small cutters that are often difficult to machine. Solution: Axtra3D’s Lumia X1 machine pairs with extra-strong materials and can quickly print molds for fast prototyping.

Quantis

FEBRUARY 10, 2023

Ideally, all machines run trouble-free. Malfunctions, worn out spare parts, missing components that throttle the performance of the machines, or in the worst case bring them to a standstill. Does one now create a digital twin of the plant, or does one make use of machine learning, or algorithms to detect faults using AI.

Robotics Business Review

JUNE 17, 2024

coboworx offers robotic solutions for machine tending and palletizing. The company currently offers systems for palletizing and machine tending applications. The company says future developments will include applications for welding, packaging, and material flow in intralogistics. million (about $12.2

Fabricating & Metal Work

MARCH 20, 2025

Developed for manufacturers across the Midwest and Southern Ontario challenged by labor shortages and increased production goals, KUKAs interactive curriculum featured autonomous mobile robots (AMRs), automated machine tool solutions and welding robotics. The KR FORTEC is suitable for a wide range of applications.

Automation Mag

JANUARY 13, 2023

“In 2023, cobot automation will become more sophisticated yet more straightforward to use,” predicts Joe Campbell, senior manager of applications development and strategic marketing at UR. “We A significant share of new cobot-powered turnkey systems now handle welding applications, according to UR.

Modern Machine Shop

SEPTEMBER 20, 2023

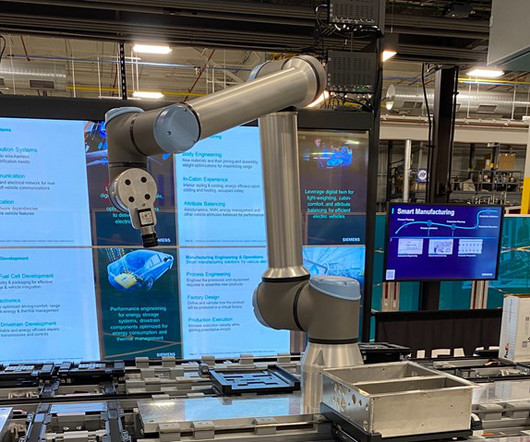

Shops are increasingly interested in automation as a solution to labor shortages or as a way to increase revenue through lights-out machining. Automation isn’t just for machine tending. This cobot is part of Siemens ’ Smart Factory Showcase at LIFT in Detroit, which attendees at TASC will have the chance to visit.

Fabricating & Metal Work

AUGUST 12, 2022

This includes supporting future-forward technologies such as AI and machine learning, which allow advanced users to leverage unlimited external computing power. The Future of Smart Machines: See firsthand why startups love Kawasaki’s KRNX API plugin for advanced automation.

Robotics Business Review

JANUARY 17, 2024

Source: Flexxbotics Flexxbotics has announced that its robotic technology is now compatible with FOBA Laser Marking + Engraving products for machine tending. Connecting robotic machine tending with our FOBA laser-marking solution using Flexxbotics provides an even greater return on investment,” stated Jeffrey A.

Design World

JULY 26, 2022

We also cover Sorbothane material’s properties, the company’s new standard products (launching this fall), and how its online Design Guide Calculators can support your application. This proprietary material is ideal for engineering design applications that require shock absorption, vibration isolation, and acoustic damping.

Modern Machine Shop

NOVEMBER 24, 2024

Norton | Saint-Gobain Senior Application Engineer Taqwa Gilani points to both MRR and its width-normalized form, MRR′, as key indicators of grinding operation productivity. Machine deflection and vibration are also closely linked to applications with high grinding forces and low machine stiffness.

Robotics Business Review

MAY 17, 2024

They included collaborative and industrial robots, as well as workcells for applications such as welding and palletizing. provides systems for applications including assembly, coating, dispensing, materials handling, material cutting and removal, packaging, and clinical laboratory specimen processing. touted its 4.7 (out

Gary Mintchell

SEPTEMBER 22, 2022

OnRobot — OnRobot Previews D:PLOY for Machine Tending at IMTS. D:PLOY automatically discovers and configures all the components in a robotic cell – including any leading collaborative or light industrial robot arm and tools – while also integrating external I/O from sensors and machines. Click for more information.

Modern Machine Shop

JANUARY 7, 2025

The 2024 Japan International Machine Tool Fair (JIMTOF) was held November 5-10, 2024 at the Tokyo Big Sight convention center. Photos provided by Modern Machine Shop. Examples of both were on display at the 2024 Japan International Machine Tool Fair (JIMTOF), held November 5 through 10, 2024 at the Tokyo Big Sight convention center.

Robotics Business Review

NOVEMBER 5, 2024

The New York-based company and founding partner of the New York Robotics Network said it plans to market READY’s application programming interface (API) with its own training software. StandardOS provides developers and AI researchers with tools for building applications, integrations, and more. Imagine a robot unloading a UPS truck.

Fabricating & Metal Work

FEBRUARY 7, 2025

Jorgensen Conveyor and Filtration Solutions FlexForce high-pressure coolant system for through-spindle coolant system (TSC) applications. In addition to manufacturing a robust line of standard industrial parts washers, polishers and deburring machines, the companies also offer custom solutions to meet specific customer requirements.

Modern Machine Shop

NOVEMBER 22, 2022

Matching applications to their optimal superabrasive grinding wheels can reap dividends through improved part quality and throughput, making deep knowledge of grain, bond and coating properties vital for grinding machine users. Likewise, the most expensive diamond or CBN wheel may not be the ideal choice for an application.

i4.0 today

MARCH 5, 2025

Designed for high-speed and precise operations, the D-Bot achieves movement speeds of up to 200 degrees per second, with an accuracy of 0.02mm, ensuring optimal performance in various industrial applications. The D-Bot includes advanced safety features compliant with Pld Cat.

Expert insights. Personalized for you.

We have resent the email to

Are you sure you want to cancel your subscriptions?

Let's personalize your content