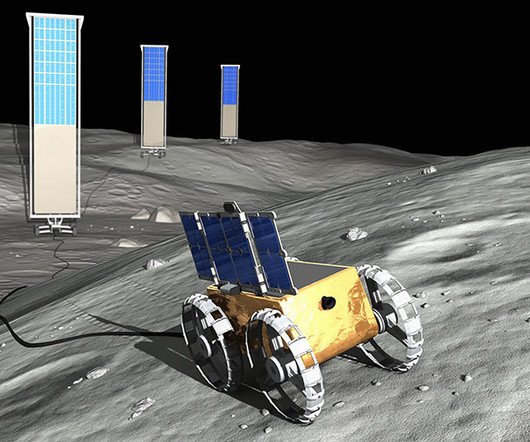

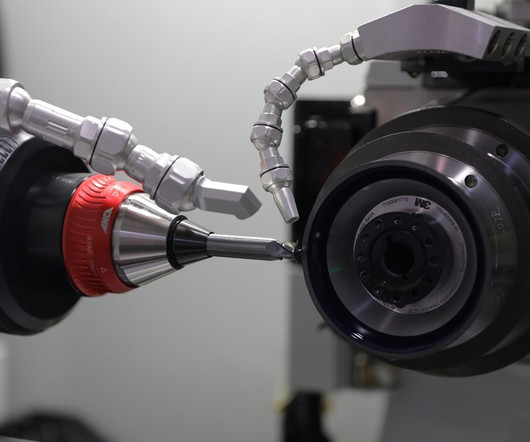

Engineers to develop robot maintenance crews in space

Manufacturer's Monthly

FEBRUARY 12, 2024

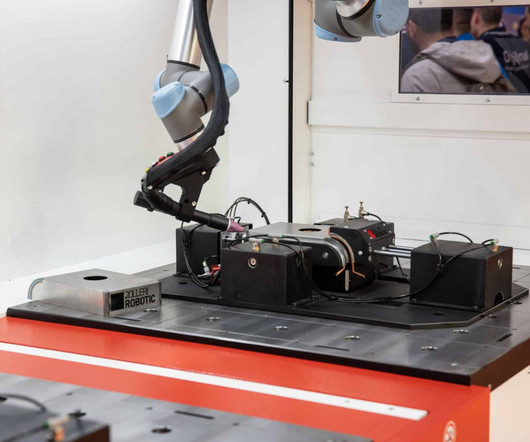

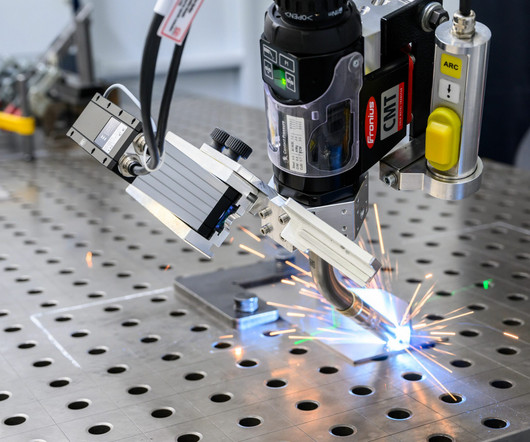

to research and develop robotic maintenance of satellites while in orbit in a step to extend the lifespan of vital space infrastructure. The new project will develop robotic satellite technologies to reliably connect with other satellites to perform in-orbit repairs and maintenance. billion market.

Let's personalize your content