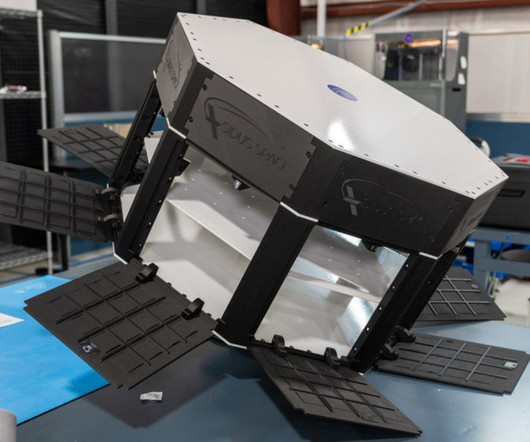

Q5D’s printed electronics techniques solve designer frustrations

Design World

MARCH 4, 2025

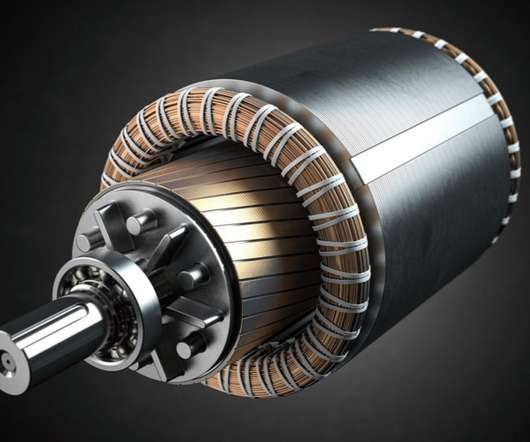

Simon Baggott of Q5D Technologies explains how new techniques simplify manufacturing for the automotive and aerospace industries. Whether youre creating vehicles, vessels, aircraft or consumer electronics, the near-constant tension between aspirational innovation and physics or economics will be all too familiar.

Let's personalize your content