OCIF invests in SAIT Aerospace Materials Composite Lab

Canadian Manufacturing

DECEMBER 11, 2024

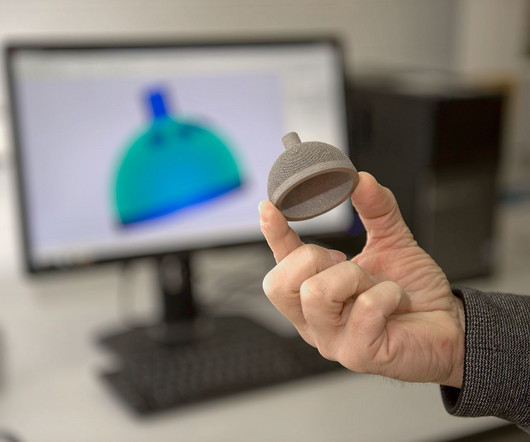

CALGARY — The Opportunity Calgary Investment Fund (OCIF) is investing up to $709,000 over the next three years into the Southern Alberta Institute of Technology’s (SAIT) Aerospace Composite Materials Lab (ACML) to strengthen Calgary’s aerospace sector and diversify the city’s economy.

Let's personalize your content