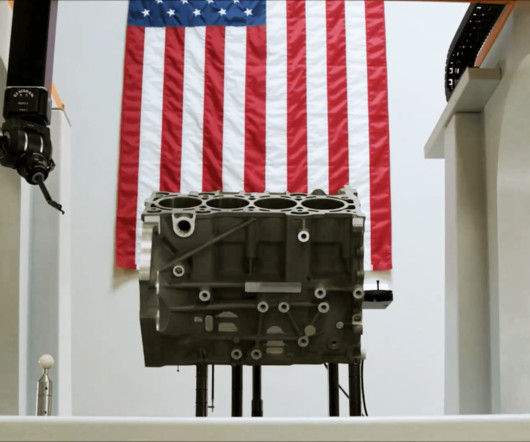

Adaptation, Business Continuity & Cobots: Quality Inspection

Universal Robots

JUNE 4, 2020

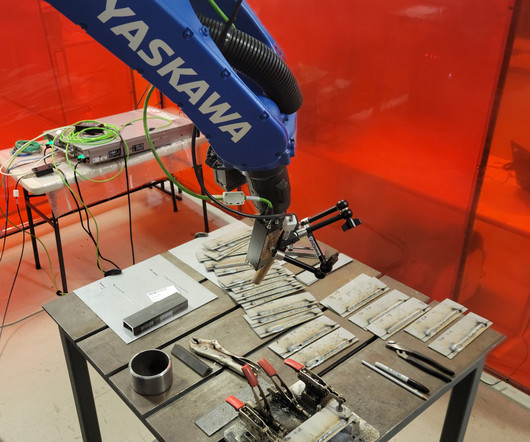

This is the second in a series of blog posts exploring the many ways in which cobots support adaptation and business continuity in uncertain times. Each post focuses on a popular application for UR collaborative robots from Quality Inspection to Welding.

Let's personalize your content