OPC Foundation News From Hannover

Gary Mintchell

APRIL 27, 2023

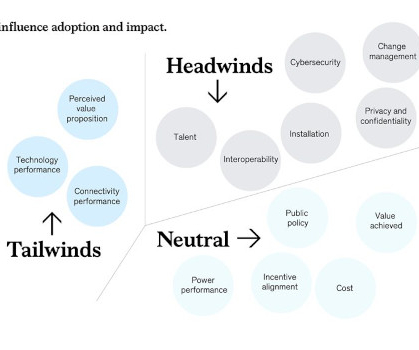

It also brings up a concept dear to me—interoperability. Bitkom and the OPC Foundation cooperate for the common goal of establishing and implementing interoperable interfaces for Industrie 4.0 Together, they want to contribute to the establishment and implementation of interoperable interfaces in the context of Industrie 4.0

Let's personalize your content