Mold Builder Meets Increased Domestic Demand With Automated Cells

Mold Making Technology

JUNE 22, 2023

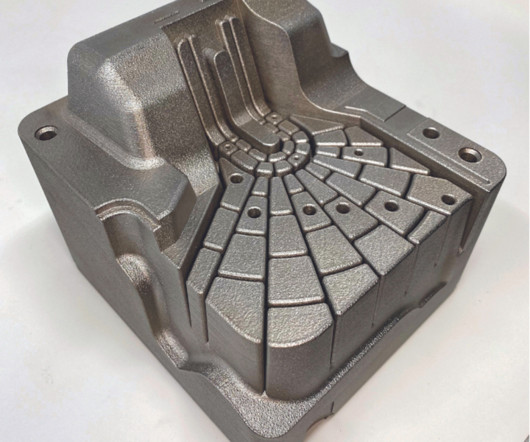

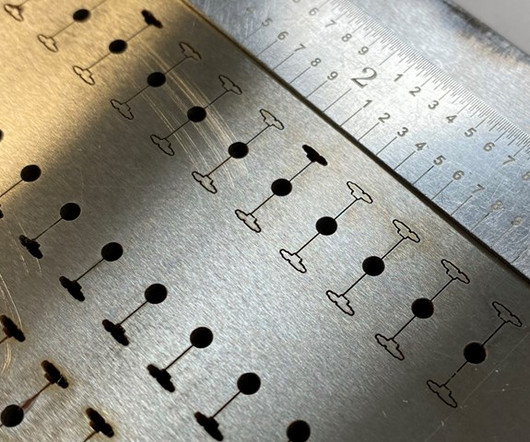

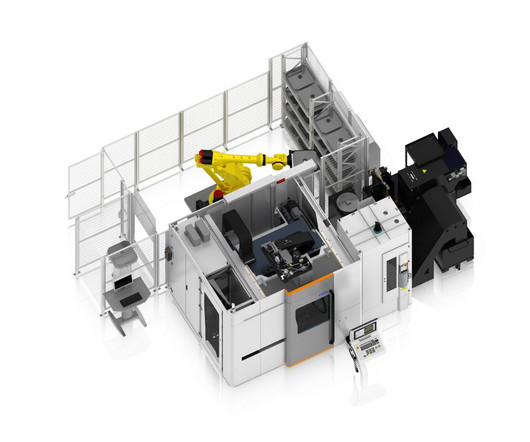

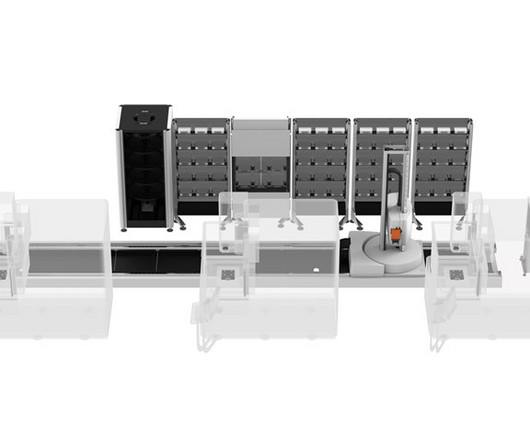

Regarding its production equipment and strategies, the shop started with basic CNC machine technology and progressed to include EDM , high-speed milling capabilities and automated cells. Solution : Automated machining cells involving GF Machining and System 3R EDM, milling and pallet-changing equipment.

Let's personalize your content