Metal AM Advances in Composite Tooling

Mold Making Technology

JANUARY 26, 2023

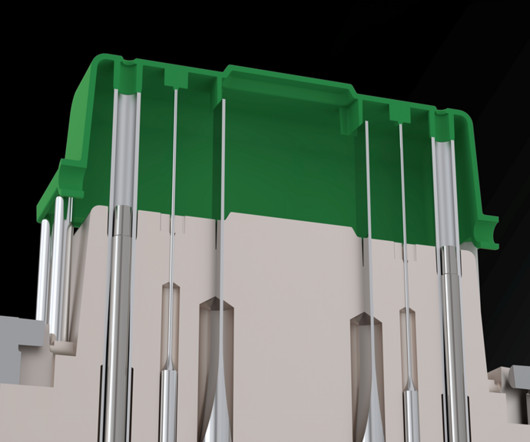

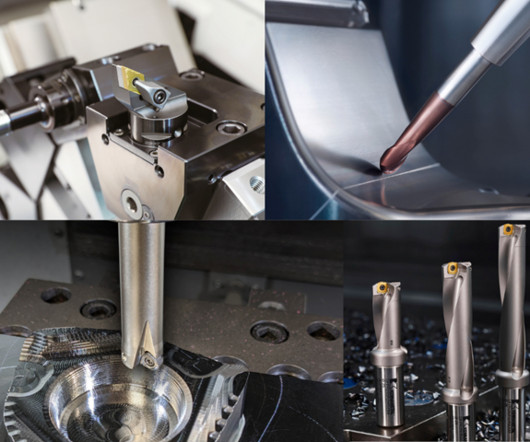

Tooling is a vital element of any successful manufacturing program for composite parts, but it is often one of the last aspects considered during the development process. In this article, we’ll cover several metal additive technologies and describe the types of tools or tool components they’re being used to produce and why.

Let's personalize your content