Demand for integrated robot control surges

Robotics Business Review

MAY 23, 2024

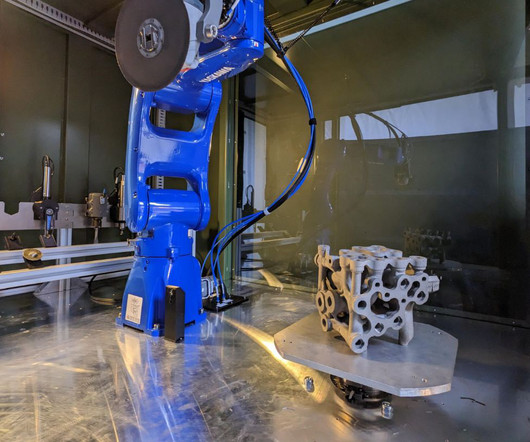

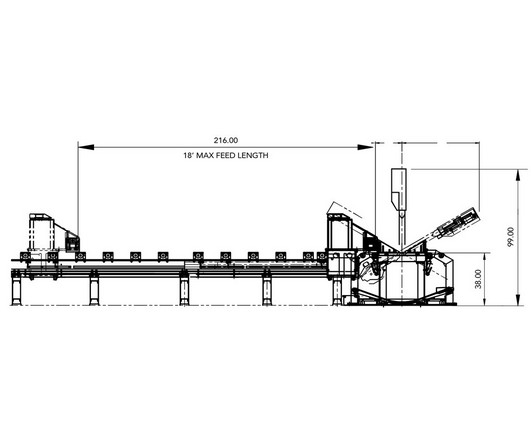

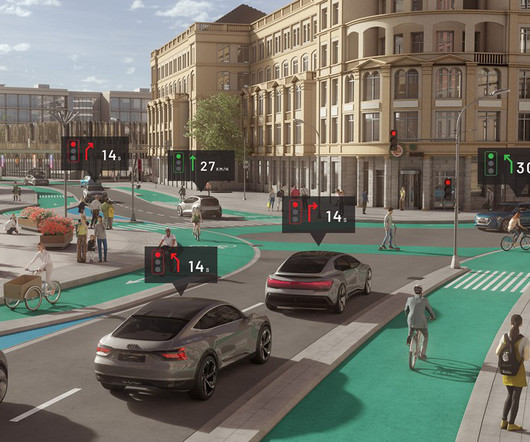

In fact, automation suppliers have been offering solutions for machine-integrated robot control for many years, but with the strong increase in the adoption of robots since 2021, demand for integrated control has surged. Partners of Siemens SRCI Robot Control System | Source: Siemens What is machine-integrated robot control?

Let's personalize your content