10 Ways Additive Manufacturing and Machining Go Together and Affect One Another

Modern Machine Shop

DECEMBER 1, 2022

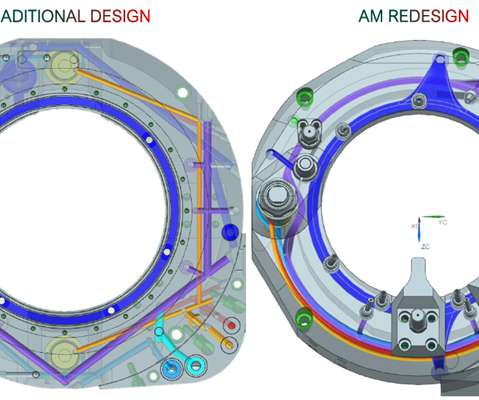

A donut-shaped machine tool component called the AKZ FDS adapter illustrates the increasingly intricate links between additive manufacturing (AM) and CNC machining. A version of this article was our cover story in the December 2022 issue of Modern Machine Shop. This photo and the drawing below courtesy of DMG MORI.

Let's personalize your content