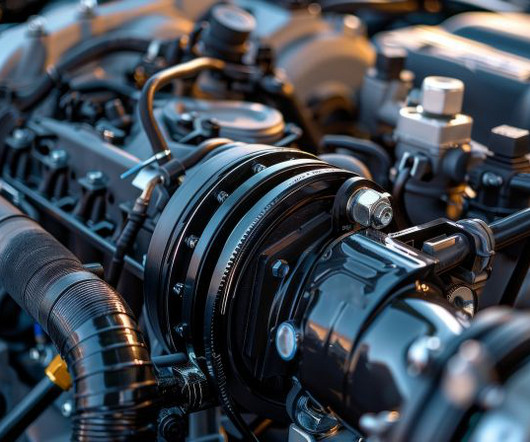

How to Start a 3D Printing Service Bureau

Additive Manufacturing

MARCH 13, 2023

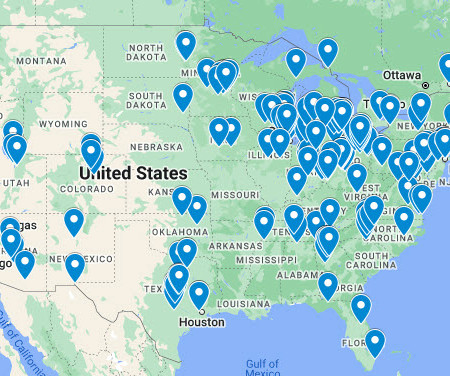

The beauty of today’s manufacturing environment is that anyone can start a 3D printing service bureau and begin printing parts today. According to a recent report by Persistence Markets , the 3D printing service bureau industry is projected to surge eight times the size of its present state over the next decade.

Let's personalize your content