How robotics and automation can benefit from 3D printing, explains Replique

Robotics Business Review

JULY 6, 2024

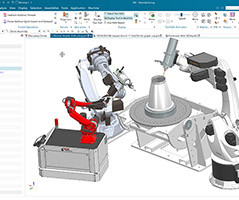

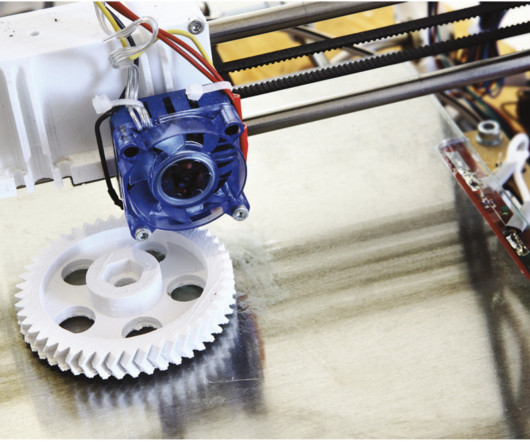

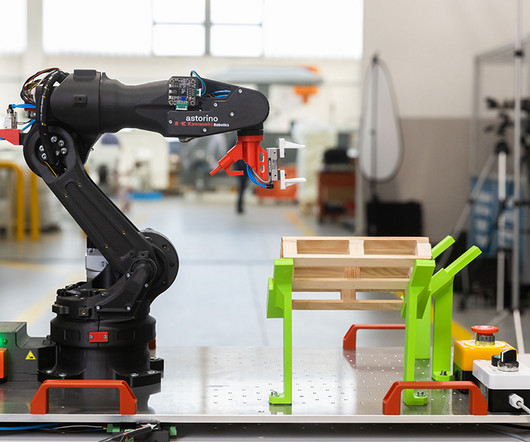

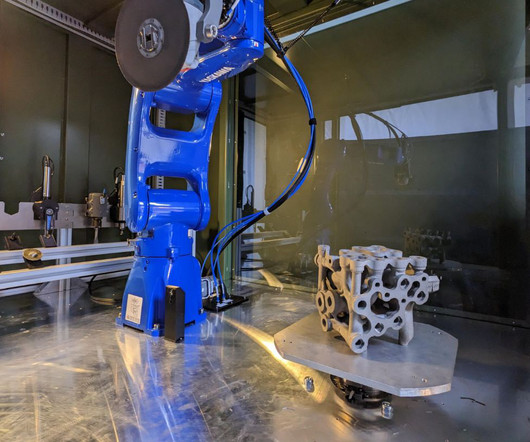

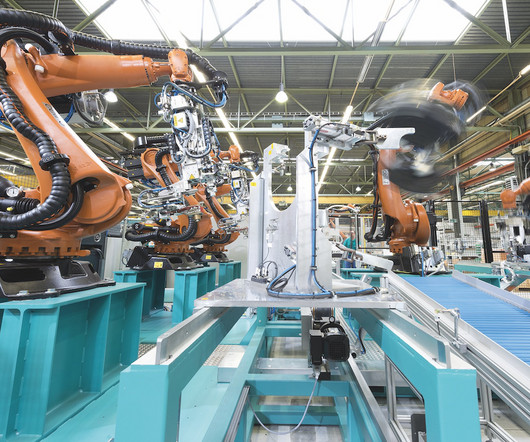

Robotic arms in large-scale 3D printing deposit materials layer by layer, transforming production. Source: Replique In the realm of modern manufacturing and automation, the integration of robotics continues to redefine industry standards. Additive manufacturing plus robotics can transform industries.

Let's personalize your content