3D Printing Accelerates R&D Process For Prototyping Molds

Mold Making Technology

FEBRUARY 27, 2025

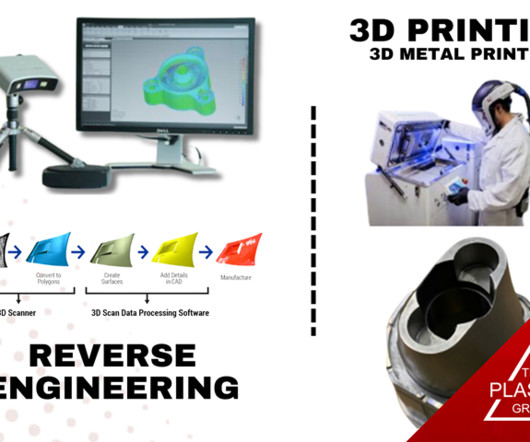

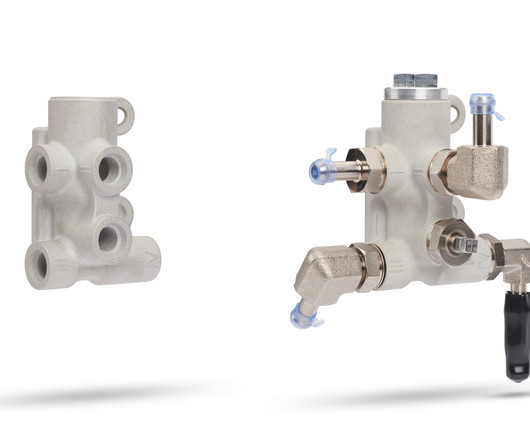

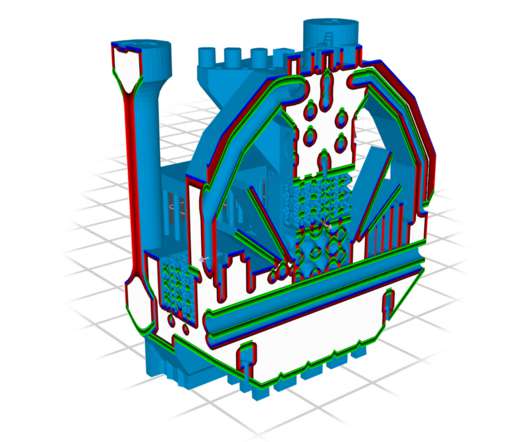

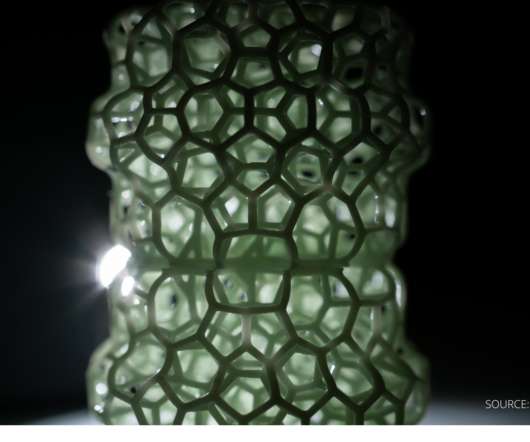

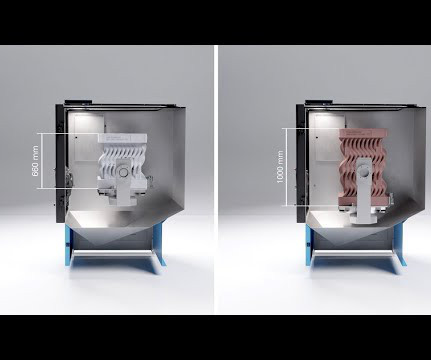

However, 3D printing offers an accelerated path for prototyping molds. Specifically, LSI Solutions wanted to find the right 3D printing technology to pair with a specific material grade, Ultracur3D RG 3280, from the chemical solutions company, Forward AM. Enter Axtra3D’s printer for injection molding.

Let's personalize your content