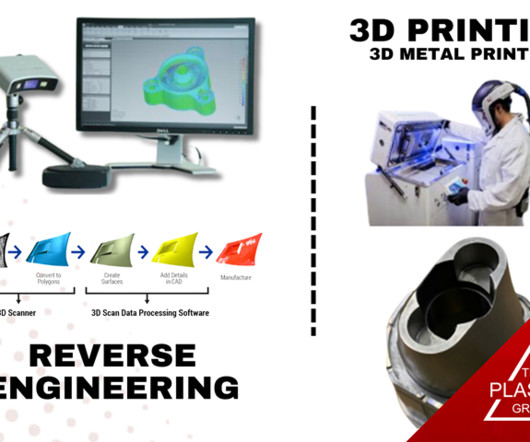

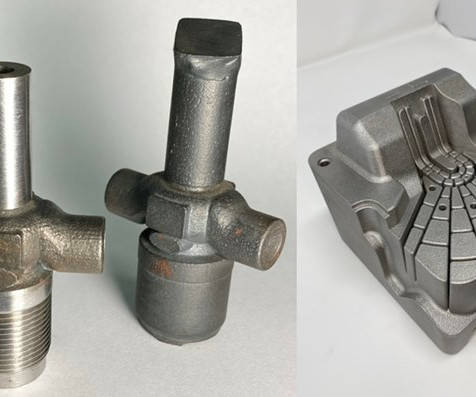

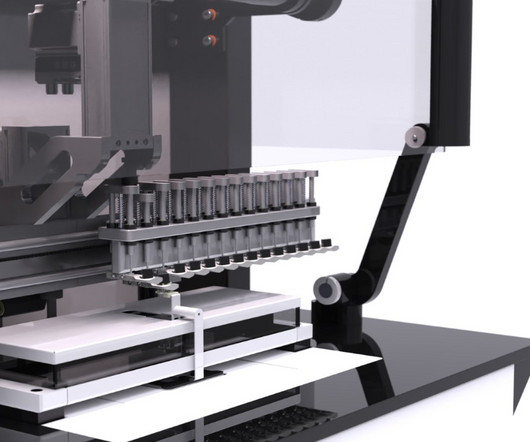

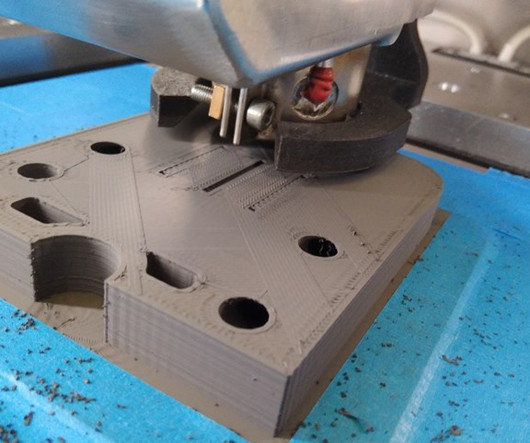

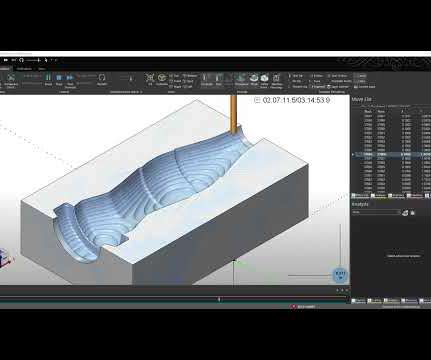

Cross-Functional Group Targets Metal 3D Printing Design, Engineering Services

Mold Making Technology

MARCH 15, 2024

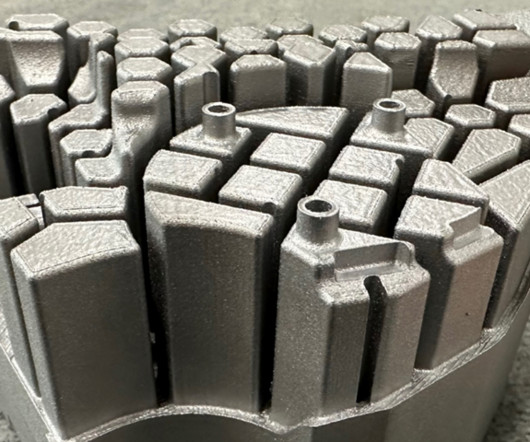

Source: The Plastek Group The Plastek Group is a cross-functional group of engineers covering multiple disciplines, from package development, mold design/manufacturing and molding/assembly, with an emphasis on collaboration and quality.

Let's personalize your content