Video: Hybrid Manufacturing Without Melting: Hermle’s Metal Powder Application (MPA) Process

Mold Making Technology

JANUARY 2, 2025

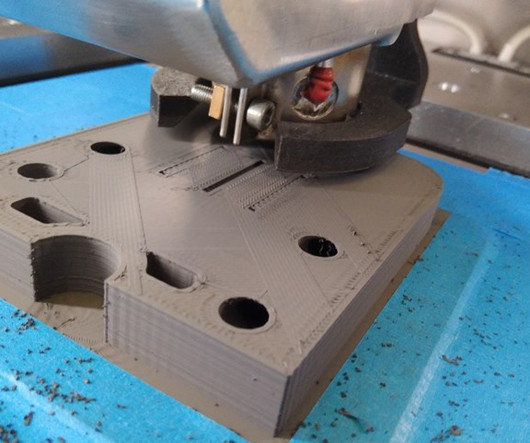

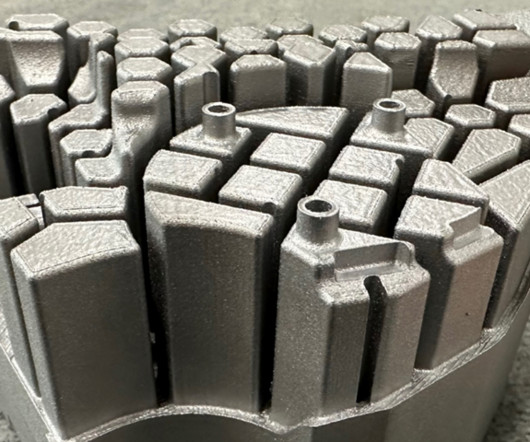

The process supports the precise addition of material, such as conformal copper areas added to injection mold tooling to improve cycle times. Initially, most applications for MPA had to do with conformal cooling, introducing copper into mold tooling for heat dissipation to improve cycle times.

Let's personalize your content