Pennsylvania Mold Builder Doubles Footprint, Maintains Quality and Company Values

Mold Making Technology

APRIL 6, 2023

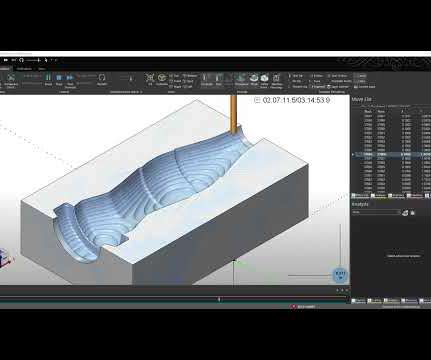

We mainly produce Class 101 tooling for the medical, consumer and automotive industries. Most of these molds use modern hot gating systems to reduce customer cycle time and decrease scrap. Produces Class 101 tooling for the medical, consumer and automotive industries. Quality Mold Inc.

Let's personalize your content